ShokWaveRider

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

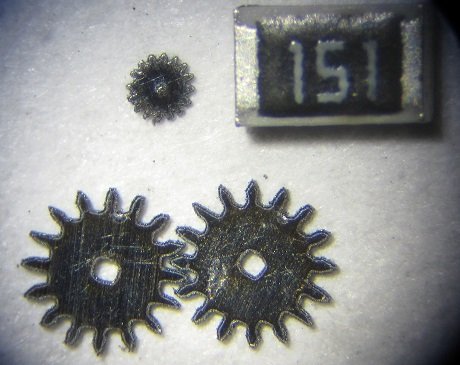

Being an Engineer and into Radio Controlled model building (building more than flying usually), I found these machines intriguing. The idea of making widgets sounds like fun.

Completely extravagant, will never get a return on my investment but what the heck.

I ordered a FlashForge Creator X dual Extruder system.

I am interested in hearing from other 3D Printer owners.

Completely extravagant, will never get a return on my investment but what the heck.

I ordered a FlashForge Creator X dual Extruder system.

I am interested in hearing from other 3D Printer owners.