I just bought an LED bulb, a 75W-equivalent, for the breakfast area ceiling fan/light. This is the area that is most often lighted. I had bought a 60W-equivalent a while back, just to see what the output light looked like. And I really do not see the advantage compared to the newer CFLs, other than the LEDs are dimmable and can be made into spot lights.

I still have so many CFLs, and as I am happy with the light they put out, cannot see myself spending a lot more for LEDs which are not more efficient. The local Costco has a pack of 4 60W-equivalent CFLs for $0.88 (subsidized by the local power company). Son of a gun!

Early generations of CFLs had yellowish/greenish light. They were also a bit dim after being switched on, then slowly brightened up. However, the newer ones I bought at Costco turn on instantly and have good light.

So, I will not be buying any more LEDs. The LEDs are dimmable, but I do not use dimmers anyway.

I agree with this - light fixture designers and bulb manufacturers need to change their thinking from mere Edison-filament replacements (see my recent post). Separating the electronics from the LEDS would be a good step. Build the electronics into an easily replaced module that could reside in the fixture, more room for the LEDS, and the electronics would be away from the heat of the LEDs.

A 60W equivalent presently uses about 20 LEDs, at ~ 3.3V each, that's 66 volts, so the step down isn't the big issue - this is all done with switching circuits, and some capacitor storage to avoid flicker while the 60 cycle power goes through its sinusoid.

Further, just providing a low DC voltage like 6V or so doesn't solve much. LEDs are current devices, the voltage is a by-product of their design and the current that is applied. You can't just feed them voltage, you need to feed them current. You can't do that from a common source like a breaker box. For example, turn on one light, and you need to supply X amps. Turn on two and now you need 2X amps. It just doesn't work from a common supply. But voltage devices do work from a common supply, they draw the current they each need as a function of voltage.

Even with low voltage DC, you would still need a switching circuit to provide a constant current to the LEDs. So you haven't eliminated much in the way of electronics anyhow. You can use a plain old resistor to limit current at a given voltage (this is common with low power LEDs), but the R wastes energy, a switching circuit is more efficient.

-ERD50

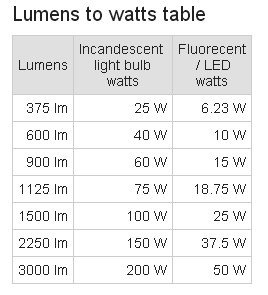

I have not taken apart a 120V LED to see the internal construction or the circuit. The LEDs I bought on eBay from China a few years ago to retrofit into my motorhome were meant for 12V applications. See photo below. The module diameter is about the size of a thumbnail, with an aluminum backing to be mounted onto a heat sink. The ones I got took 10W, and output 600 lumens or the same as a 60W incandescent bulb.

The module has 9 LEDs arranged as a 3x3 matrix, and connected as 3 parallel strings of 3 LEDs in series. So, the voltage is roughly about 10V, and the current about 1/3A through each string. I built a current source to drive them, as the 12V lead-acid battery voltage may range from 12.2V (under discharge) up to 14.2V when heavily charged.

I converted 10 of the 14 light fixtures inside the motorhome to these LEDs, and when I turned them all on, my wife had to wear shades.

Good thing I put in the dimming capability. See the knobs and potentiometers I retrofitted into the light fixtures. The light quality is much better and less yellowish than the original 12V incandescent bulbs. And the light stays constant despite the varying voltage.

I am quite happy with these home-made lights. Each LED cost $6 back then, and the circuit for each fixture cost another $6 because I already had some parts on hand. The current regulator is a switching circuit, but the inductor is not visible because of the photo angle.

For boondocking, the power I use for lighting is negligible compared to what I use for the laptops or to watch TV.