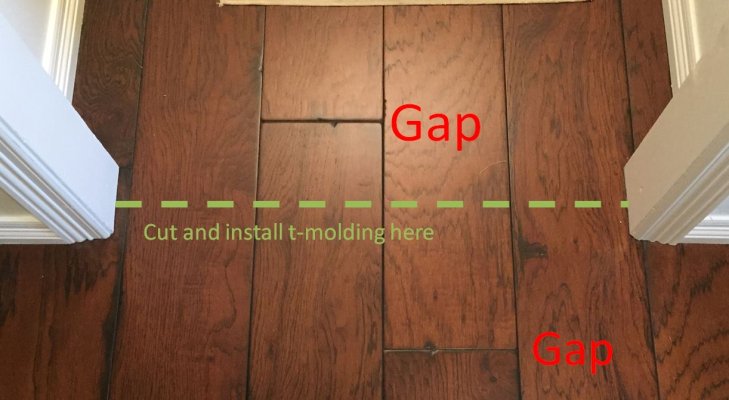

Last year we had an engineered wood floor installed, floating. They left expansion gaps along the walls (under the baseboards) but there are no gaps between the rooms. One section has developed a couple 1/8" gaps on the short end of the boards in a hallway that ends with no expansion gap (there is a step down and they just glued that edge rather than letting it float. sigh). These gaps are near an interior doorway. See photo.

My plan is to plunge cut the boards across the doorway to remove a 1" strip, tap the offending boards back in place to close the gaps on each side, then install a t-molding that covers the gap.

Is there a better way to deal with this? Any reason my plan will backfire once I start cutting our wood floors?

My plan is to plunge cut the boards across the doorway to remove a 1" strip, tap the offending boards back in place to close the gaps on each side, then install a t-molding that covers the gap.

Is there a better way to deal with this? Any reason my plan will backfire once I start cutting our wood floors?