Just put down a new garage floor with this stuff.

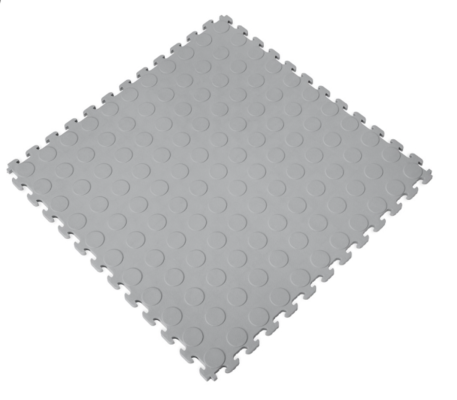

Raised Coin Pattern PVC Tiles

Definitely in Blow That Dough territory, but available for less at other sites. This link is to the manufacturer. Very easy to install and I'm extremely pleased with it.

The previous owner had put some kind of epoxy coating on the garage floor which looked nice but was quite slippery when wet. As my balance is nowhere as good as it used to be, that scared me a little, so I wanted a nonslip surface.

All you need to install it is a rubber mallet, and most of the time not even that. The pieces interlock securely, and they have air channels on the bottom to eliminate condensation concerns. Also very easy to cut to fit the edges with just a regular utility knife.