Boho

Thinks s/he gets paid by the post

- Joined

- Feb 7, 2017

- Messages

- 1,844

Re: air cleaner with a mind of its own:

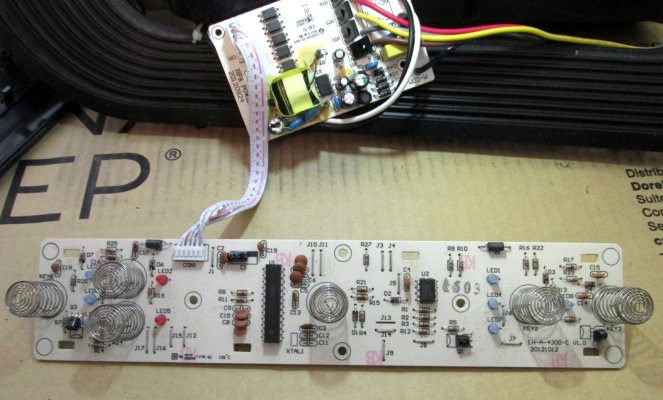

I got the screwdriver and opened up the air cleaner but there was no visible dirt at the switches that I could see. I think they're capacitive switches that you barely have to touch (when they work). I didn't know what to do to make a better connection between the springs and the foil looking thing they press against so I just reassembled it and cleaned up some of the interior of the case. The motor and fan blades didn't look so dirty so I didn't bother to access that area for a complete cleaning. It seemed like I accomplished nothing but it's working now. Maybe the dust that I did clean was causing static or reseating the switches created better contact somehow.

So, I tried opening it to clean it from the inside and discovered two of the six screws aren't ordinary Philips heads. A 1/8" allen wrench fit one of them well enough that I was able remove it with difficulty. They're T20 tamper proof screws but the one I removed had a short stem so the allen wrench fit. For the other one I ordered a screwdriver from Hong Kong ($2) so I'm suddenly extra interested in a resolution to their conflict.

I got the screwdriver and opened up the air cleaner but there was no visible dirt at the switches that I could see. I think they're capacitive switches that you barely have to touch (when they work). I didn't know what to do to make a better connection between the springs and the foil looking thing they press against so I just reassembled it and cleaned up some of the interior of the case. The motor and fan blades didn't look so dirty so I didn't bother to access that area for a complete cleaning. It seemed like I accomplished nothing but it's working now. Maybe the dust that I did clean was causing static or reseating the switches created better contact somehow.