Midpack

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

I have a problem, and I am hoping for a better solution than the one I've come up with.

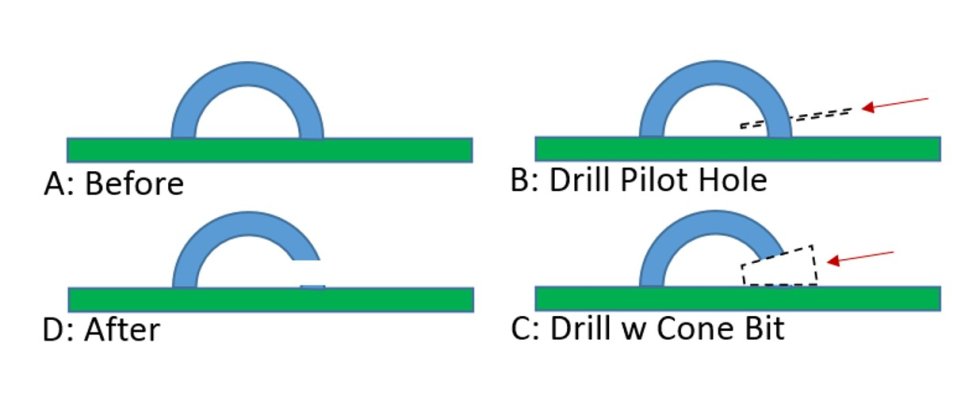

All I've come up with is drilling a pilot hole as shown in pic B. And buying a cone shaped bit to drill and enlarge the hole as shown in pic C. I would proceed cautiously, drilling and looking repeatedly (with flashlight), in the hope that would prevent me from nicking the green surface.

Any other cost effective ideas?

- I am starting with pic A. The fiberglass thickness and hole are about 1/2-5/8" for some scale.

- I am trying to drill a hole thru a piece of fiberglass channel (blue) that is bonded to another flat fiberglass surface (green). It was supposed to have a hole drilled as shown in pic D, but it was missed by the manufacturer.

- Space is very limited (I think a basic power drill at an angle will fit, but barely), and I can only drill from one direction (right to left in pic).

- The hole would have been constant OD/parallel (like pic D), but it does not have to be parallel to the green surface, as long as the bottom of the hole is (like pic C).

- The hole must be as close to the green surface as possible...

- ...but it's critical that I don't nick/drill into the green fiberglass while drilling through the blue.

- I am only drilling two holes, and the project is over.

All I've come up with is drilling a pilot hole as shown in pic B. And buying a cone shaped bit to drill and enlarge the hole as shown in pic C. I would proceed cautiously, drilling and looking repeatedly (with flashlight), in the hope that would prevent me from nicking the green surface.

Any other cost effective ideas?

Attachments

Last edited: