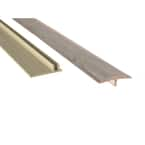

Agree with pb4uski on using the T channel. You can first place the U portion, and then when installing the LVP, you have a reference for your expansion gap.

One warning on this stuff. Many of the brands are one and done. This is especially true on the versions that use a crushable fiber on the T portion. Once you place it down, you will damage it pulling it up. You can actually say that for almost any transition strip.

I recommend cutting a few inches off (you almost always have extra) and experimenting with it before you put down the full threshold.

On this latest work I did on the youth camp, we felt it would have quite a bit of abuse so we went with the traditional aluminum transition strip. I nailed it too hard. But, hey, it is what it is for now. We're probably going to replace that carpet soon anyway.

This picture is less of a humble brag as it may not be my best work (especially my cut at the door casing), but it gives you an idea what it will look like. We also accidentally lined up the knot pattern. Try to avoid that. I was focused too much on the seams and not enough on the big picture. More truth on some of my workmanship glitches.

Oh, another thing. This LVP transitions to a shower. We decided to leave the gap more like 3/16" and fill it with high quality silicone caulk. The small floor is going to have to expand in the other direction, although the caulk has some give. These are the trickier situations.