Vincenzo Corleone

Full time employment: Posting here.

- Joined

- Jul 20, 2005

- Messages

- 617

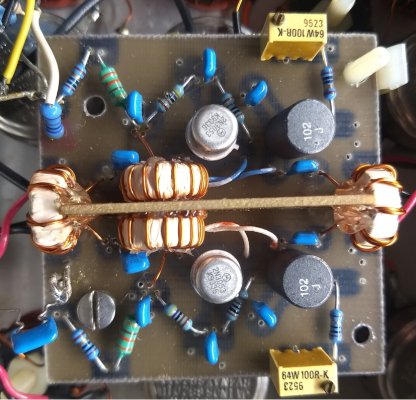

When I was a kid, I used to take broken electronic things apart and mess around with the electronics on the PCB. I learned to solder and to use a de-soldering wick to remove components from the board and then solder them back. I learned how to identify the various electronic components. I don't recall doing anything sophisticated, just learned stuff here and there.

Anyway - I thought it would be neat if, instead of replacing various electronic devices that break, I could just identify the bad electronic component(s), swap out a bad capacitor or transistor, and fix the problem. I'm pretty good with solder and a soldering gun. At the moment, I have an alarm clock, the display on which doesn't work that I'd love to be able to fix.

If I'm not mistaken, in order to identify bad components, I'd need a multimeter. Is that right? I never used one before but have seen YouTube videos and it doesn't look like rocket science. Any multimeter recommendations? Anything else I need to be aware of if I want to pursue this?

Anyway - I thought it would be neat if, instead of replacing various electronic devices that break, I could just identify the bad electronic component(s), swap out a bad capacitor or transistor, and fix the problem. I'm pretty good with solder and a soldering gun. At the moment, I have an alarm clock, the display on which doesn't work that I'd love to be able to fix.

If I'm not mistaken, in order to identify bad components, I'd need a multimeter. Is that right? I never used one before but have seen YouTube videos and it doesn't look like rocket science. Any multimeter recommendations? Anything else I need to be aware of if I want to pursue this?

Do not buy cheap tools!

Do not buy cheap tools!

Thought it would last forever

Thought it would last forever