ERD50

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

Yes, the mechanical fastener type.

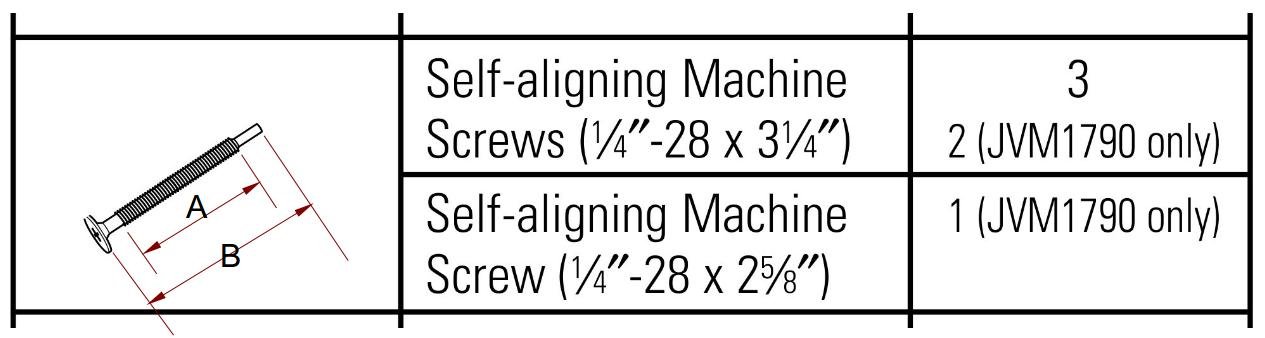

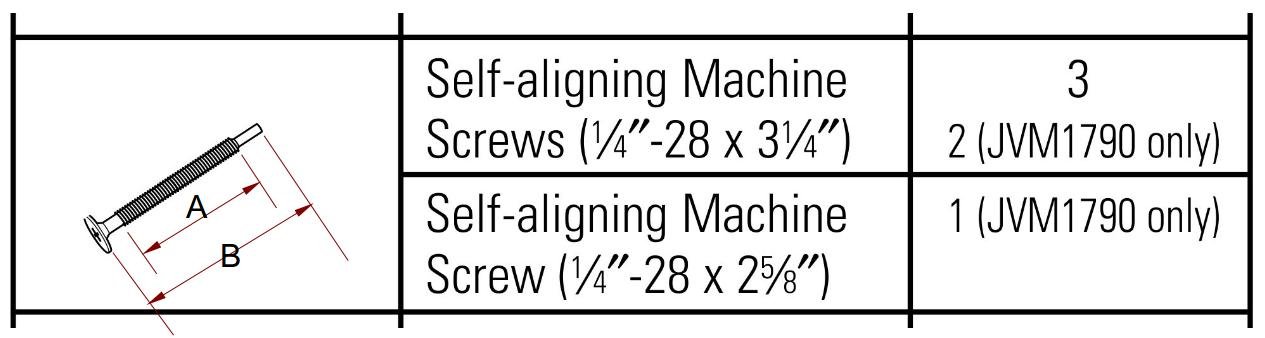

Seems like an easy question. Measure it. But from end-to-end, or the thread length?

This is my on-going saga with my GE u-Wave/fan. Three screws go through the top kitchen cabinet into the u-Wave chassis. It calls for a shorter one in one location (there must be a reason, and yes, there is something that it bottoms out on when I carefully hand-thread it in).

But when I measured the screws to double-check, they were all longer than stated. Figured it should be easy to verify with GE, but no. Got a run-around, transfers, was sent out two different hardware kits, both were supposed to be 'right' but the double-checked 'right' one doesn't even have any of these special 'self aligning' screws in it. I can't seem to get to a technical person (one was supposed to call me today...)

Now, the thread length is pretty close to the 3 1/4 and 2 5/8th they call for. These are probably correct... but if I mess up the install, I don't want to fight with GE over this (they claim I'm protected now that I called, but I don't trust that, and they wouldn't send me an email to that effect).

A google search of 'self aligning machine screw' didn't turn up much, neither did a scrub of the Grainger and McMaster-Carr catalogs. I know I'm being [-]a bit[/-] overly paranoid here, but the oven is expensive (combo uW, convection oven and exhaust fan), and the cost and frustration is simply not worth the risk. I don't want to 'guess' at how far these screws can go inside the cabinet, and I don't want them sticking up inside the cabinet with spacers either.

Here's a marked up from the manual. A or B? Any mechanical engineers/machinists know what is the standard for measuring length on these (if GE followed the standard?)?

I do have a call into the installers from the retail appliance company. I suspect they will be able to help, but I was hoping to close the loop with GE, and the installers were out for the day - they will call tomorrow. Oh, and if I were to use regular screws, I can see where I would run the risk of cross-threading, and those threads are inside the oven, so I want to do this right.

Any ideas?

-ERD50

Seems like an easy question. Measure it. But from end-to-end, or the thread length?

This is my on-going saga with my GE u-Wave/fan. Three screws go through the top kitchen cabinet into the u-Wave chassis. It calls for a shorter one in one location (there must be a reason, and yes, there is something that it bottoms out on when I carefully hand-thread it in).

But when I measured the screws to double-check, they were all longer than stated. Figured it should be easy to verify with GE, but no. Got a run-around, transfers, was sent out two different hardware kits, both were supposed to be 'right' but the double-checked 'right' one doesn't even have any of these special 'self aligning' screws in it. I can't seem to get to a technical person (one was supposed to call me today...)

Now, the thread length is pretty close to the 3 1/4 and 2 5/8th they call for. These are probably correct... but if I mess up the install, I don't want to fight with GE over this (they claim I'm protected now that I called, but I don't trust that, and they wouldn't send me an email to that effect).

A google search of 'self aligning machine screw' didn't turn up much, neither did a scrub of the Grainger and McMaster-Carr catalogs. I know I'm being [-]a bit[/-] overly paranoid here, but the oven is expensive (combo uW, convection oven and exhaust fan), and the cost and frustration is simply not worth the risk. I don't want to 'guess' at how far these screws can go inside the cabinet, and I don't want them sticking up inside the cabinet with spacers either.

Here's a marked up from the manual. A or B? Any mechanical engineers/machinists know what is the standard for measuring length on these (if GE followed the standard?)?

I do have a call into the installers from the retail appliance company. I suspect they will be able to help, but I was hoping to close the loop with GE, and the installers were out for the day - they will call tomorrow. Oh, and if I were to use regular screws, I can see where I would run the risk of cross-threading, and those threads are inside the oven, so I want to do this right.

Any ideas?

-ERD50