ronin

Thinks s/he gets paid by the post

- Joined

- Oct 21, 2003

- Messages

- 1,325

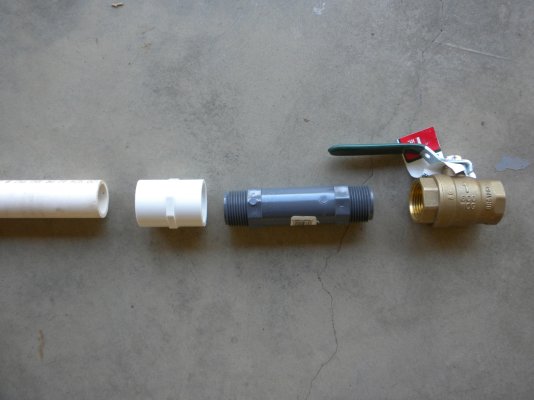

I've been trying to hook up a long water supply to the back yard using pvc. Got a new water service (1" copper) up to the house from the street and a new brass 1" ball valve w/threaded female outlet stubbed off towards the back that I am tying into. I am using a sch 80 pipe nipple into the ball valve and a pvc coupler (w/teflon tape), threaded female inlet and slip connector outlet to the line that runs out back.

Here's my issue. All glued connections in the line are water tight. But, at first I had a leak at the brass valve/pipe nipple connection. The other side of the nipple going into the pvc threaded coupler was fine. So I had to cut-off the coupler and install a new, longer nipple (because I lost a couple inches w/the cut) and reinstall the whole mess.

Now, the brass valve to pipe nipple doesn't leak, but the other end at the pvc connector does. ARGHHH! To tighten it up and see if it will seal, I have to cut the pvc pipe past the connector so that I can screw it in a turn or so without backing out the nipple from the valve on the other side. Then I need to install a coupler to splice the pvc pipe back together.

So, it either stops leaking (like that will happen ), or not. So when in doubt get a bigger hammer. Or in this case, what I want to know is if there is any reason I can't cut the threaded end off the nipple back to the smooth pvc in the middle and glue on a slip connector. Essentially I'd be making my own custom pvc pipe nipple threaded on one end (that goes into the brass valve, which doesn't leak and I don't want to disconnect or mess with) and a smooth, unthreaded end that I could glue and be pretty sure wouldn't leak again anytime soon.

), or not. So when in doubt get a bigger hammer. Or in this case, what I want to know is if there is any reason I can't cut the threaded end off the nipple back to the smooth pvc in the middle and glue on a slip connector. Essentially I'd be making my own custom pvc pipe nipple threaded on one end (that goes into the brass valve, which doesn't leak and I don't want to disconnect or mess with) and a smooth, unthreaded end that I could glue and be pretty sure wouldn't leak again anytime soon.

I don't care that I couldn't unscrew it after that because I'd have to cut it anyway if I ever had to remove it. What do you think?

Here's my issue. All glued connections in the line are water tight. But, at first I had a leak at the brass valve/pipe nipple connection. The other side of the nipple going into the pvc threaded coupler was fine. So I had to cut-off the coupler and install a new, longer nipple (because I lost a couple inches w/the cut) and reinstall the whole mess.

Now, the brass valve to pipe nipple doesn't leak, but the other end at the pvc connector does. ARGHHH! To tighten it up and see if it will seal, I have to cut the pvc pipe past the connector so that I can screw it in a turn or so without backing out the nipple from the valve on the other side. Then I need to install a coupler to splice the pvc pipe back together.

So, it either stops leaking (like that will happen

I don't care that I couldn't unscrew it after that because I'd have to cut it anyway if I ever had to remove it. What do you think?