Looking at the weather is a concept in Tesla PowerWalls as they will go/stay higher charged if they see bad weather coming your way.Thanks. This game clearly calls for a super bit of software to do the optimizing. And I do think weather prediction/anticipation could be part of it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Some truth to people who think we can be 100% renewable

- Thread starter Texas Proud

- Start date

On a different but similar plane, my Honeywell thermostat kicks on just the fan every XX minutes to keep the air in the house circulated and an even temperature.However, I do not want a large temperature swing, and use a setting change of 2F.

NW-Bound

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jul 3, 2008

- Messages

- 35,712

I am glad to hear about the battery storage that Alan had installed in the UK. This is catching on, and I am very interested in hearing about the cost. It's not at all rocket science, but all about battery cost and longevity.

There are other energy storage system makers that are lesser known than Tesla. At this point, it looks like Tesla has the lead, due to their high-volume production of batteries.

It is still expensive though. An Australian analyzed the warranty and cost to come up with the cost for each kWh of storage. At the current exchange rate of US$0.70 per AU$, it's US$0.11/kWh, using his 15.5c figure.

See: https://www.solarquotes.com.au/blog/powerwall-2-warranty/

By the way, Tesla Powerwalls have an Internet connection for remote control and also data logging for warranty purposes.

There are other energy storage system makers that are lesser known than Tesla. At this point, it looks like Tesla has the lead, due to their high-volume production of batteries.

It is still expensive though. An Australian analyzed the warranty and cost to come up with the cost for each kWh of storage. At the current exchange rate of US$0.70 per AU$, it's US$0.11/kWh, using his 15.5c figure.

At a retail cost of AUD$8,800 inc GST and 37,800 warranted kilowatt-hours of storage, that gives a cost per warranted kWh of 23.3 cents. This is 25% lower than the GCL EKwBe, 30% lower than the little known DCS PV5.0, and 40% lower per warranted kWh of Tesla’s main rival, the LG Chem Resu 10.

If you want to assume your Tesla Powerwall 2 will provide 50% more kilowatt-hours of storage than it is warranted for before it dies, then you are looking a cost per kWh of 15.5 cents. That’s pretty compelling for large users of electricity with large solar systems.

See: https://www.solarquotes.com.au/blog/powerwall-2-warranty/

By the way, Tesla Powerwalls have an Internet connection for remote control and also data logging for warranty purposes.

Last edited:

NW-Bound

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jul 3, 2008

- Messages

- 35,712

And speaking of battery cost, the LiFePO4 (lithium iron phosphate) type that I use is claimed to have the longest life among all lithium battery types. It is not commonly used in EVs and consumer electronics because it does not have the same energy density. However, it is the safest type, and is typically used in aviation.

Most LFP battery makers claim a life of 2000 cycles, at 100% depth, to 80% capacity degradation. If that is true, that is astounding.

The retail price is still around $500/kWh of capacity, so at 2000 cycles it's $0.25/kWh. Still very expensive, if we do not count the residual life at reduced capacity.

I am still waiting for the $100/kWh price point that they promise. That would be great.

Most LFP battery makers claim a life of 2000 cycles, at 100% depth, to 80% capacity degradation. If that is true, that is astounding.

The retail price is still around $500/kWh of capacity, so at 2000 cycles it's $0.25/kWh. Still very expensive, if we do not count the residual life at reduced capacity.

I am still waiting for the $100/kWh price point that they promise. That would be great.

Last edited:

The installation of the panels plus 2xPylon 2.4kWh batteries was £7,500 ($9,375). Additional batteries can be bought for under $1k and easy to self install.

https://zerohomebills.com/product/pylontech-us2000b-plus-2-4-kwh-li-ion-battery-module-48v/

ETA

We currently pay £0.145/kWh for electricity (18c/kWh)

https://zerohomebills.com/product/pylontech-us2000b-plus-2-4-kwh-li-ion-battery-module-48v/

ETA

We currently pay £0.145/kWh for electricity (18c/kWh)

Last edited:

NW-Bound

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jul 3, 2008

- Messages

- 35,712

I looked up PylonTech. It is a Chinese company that makes its own LFP (lithium ferrophosphate) as well as attached electronics. I did not hear about this company, but saw that they are partnered with Victron Energy who is a premier Dutch maker of inverters for the RV and marine segments.

The price of £700 for a 2.4 kWh battery is US$353/kWh. That's the best price I have seen for a packaged battery with an integrated BMS (battery management system).

Here in the US, several companies still sell LFP batteries that look like ordinary car lead-acid batteries at $700-900 for 1.2kWh. They are all assembled using cells made by the Chinese.

The price of £700 for a 2.4 kWh battery is US$353/kWh. That's the best price I have seen for a packaged battery with an integrated BMS (battery management system).

Here in the US, several companies still sell LFP batteries that look like ordinary car lead-acid batteries at $700-900 for 1.2kWh. They are all assembled using cells made by the Chinese.

Lakewood90712

Thinks s/he gets paid by the post

- Joined

- Jul 21, 2005

- Messages

- 2,223

Of course windmills and solar panels require energy to manufacture.

But if over their useful operating life they produce enough electricity to save more oil and gas than it takes to make them, then it is definitely a worthwhile trade.

I think the tough problem is not being able to store energy for cloudy and calm days.

Over a 25 year predicted life of a pv system, most will produce net energy in year 8 and later. A lot of energy is indeed expended to produce the cells, panels, extra wiring, hardware, install and sales transportation , roof modifications, premature damage from hail, and likely inverter replacement during the lifetime of the cells.

In my area of CA, unscrupulous solar companies, including the big ones, sell systems with panels facing north and east , to get the max KW on a roof, and max rebates/ tax credits, even if nearly useless in actual use. This is fraud IMO.

Sodium Sulfur batteries are by far the lowest cost per KW, lowest energy loss during charge / discharge, and lowest environmental damage from mining raw materials. Just a small downside, they operate at about 600 deg, F.

NW-Bound

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jul 3, 2008

- Messages

- 35,712

On the subject of solar installation, today sees the announcement of a lawsuit by Walmart against Tesla. The allegation is that 7 Walmart stores have suffered roof fire due to solar panels installed by SolarCity, a business acquired by Tesla in 2016.

Walmart wants Tesla to pay for damages as well as removing systems from all the stores.

See: After seven roof fires, Walmart sues Tesla over solar panel flaws

PS. Before embarking on the DIY solar+storage project, I spent many months studying the subject, and found that I had not been aware of some dangers that were not obvious. And I am an EE as well a tinkerer with some experiences.

The solar system I built is a low-voltage design that is not as efficient in terms of wiring costs and complexity, but it is a fail-safe design. It is suitable for a small residential system, not a large commercial installation.

.

Walmart wants Tesla to pay for damages as well as removing systems from all the stores.

See: After seven roof fires, Walmart sues Tesla over solar panel flaws

PS. Before embarking on the DIY solar+storage project, I spent many months studying the subject, and found that I had not been aware of some dangers that were not obvious. And I am an EE as well a tinkerer with some experiences.

The solar system I built is a low-voltage design that is not as efficient in terms of wiring costs and complexity, but it is a fail-safe design. It is suitable for a small residential system, not a large commercial installation.

.

Last edited:

Lakewood90712

Thinks s/he gets paid by the post

- Joined

- Jul 21, 2005

- Messages

- 2,223

How hot do the panels get?

Is it heat only from the sun or does the wiring heat up from resistance or something?

Or does the PV process generate its own heat?

Even though the panels block all the UV and infrared radiation on the roof surface, summertime temps of the air between the panels and the roof often reach 200 deg f. Some of the UV and infrared that hits the panels ends up as heat radiating thru the panels.The cells dont generate much heat themselves. If they did , systems would work in snow conditions.

Most wiring used is rated for 90 deg c, Integrity of the wiring, connections , terminals is much more critical on solar systems than low ( under 600 volt) AC wiring.

NW-Bound

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jul 3, 2008

- Messages

- 35,712

Right now, the temperature in the shade in my backyard is 112F. I just clocked the surface of my solar panels at 170F. That is hot, but solar panel fires are usually hot enough to melt glass.

The fires are electrical in nature. It happens when one of the cells in one of a series of panels gets weak, and cannot keep up with the rest. It gets driven into the reverse bias region, up to its breakdown voltage. The weak cell has to dissipate a lot of heat (similar to a Zener diode in reverse bias) and burns up.

Then, even after the cell has melted, the high-voltage DC causes arcing and the current continues to flow across gaps as wide as several inches and the fire spreads.

See the following video for arcing with just 4 panels in series.

See the following video for arcing with 500V DC (about 10 panels in series)

The fires are electrical in nature. It happens when one of the cells in one of a series of panels gets weak, and cannot keep up with the rest. It gets driven into the reverse bias region, up to its breakdown voltage. The weak cell has to dissipate a lot of heat (similar to a Zener diode in reverse bias) and burns up.

Then, even after the cell has melted, the high-voltage DC causes arcing and the current continues to flow across gaps as wide as several inches and the fire spreads.

See the following video for arcing with just 4 panels in series.

See the following video for arcing with 500V DC (about 10 panels in series)

Last edited:

ncbill

Thinks s/he gets paid by the post

That shouldn't be a problem with residential installations (12VDC to 48VDC), though, right?

NW-Bound

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jul 3, 2008

- Messages

- 35,712

Residential installations used to be high voltage, of up to 600VDC. Panels are wired in strings of perhaps 10 panels each, which then feed a string converter. Some converters have an electronic arc fault detector to shut down when an intermittent irregular current is detected.

Modern residential installations now use microinverters. Each panel is fitted with its own inverter, and the trunk is now AC instead of DC. This eliminates the hazard of DC arcing. And failure of a cell in a panel simply reduces that panel output.

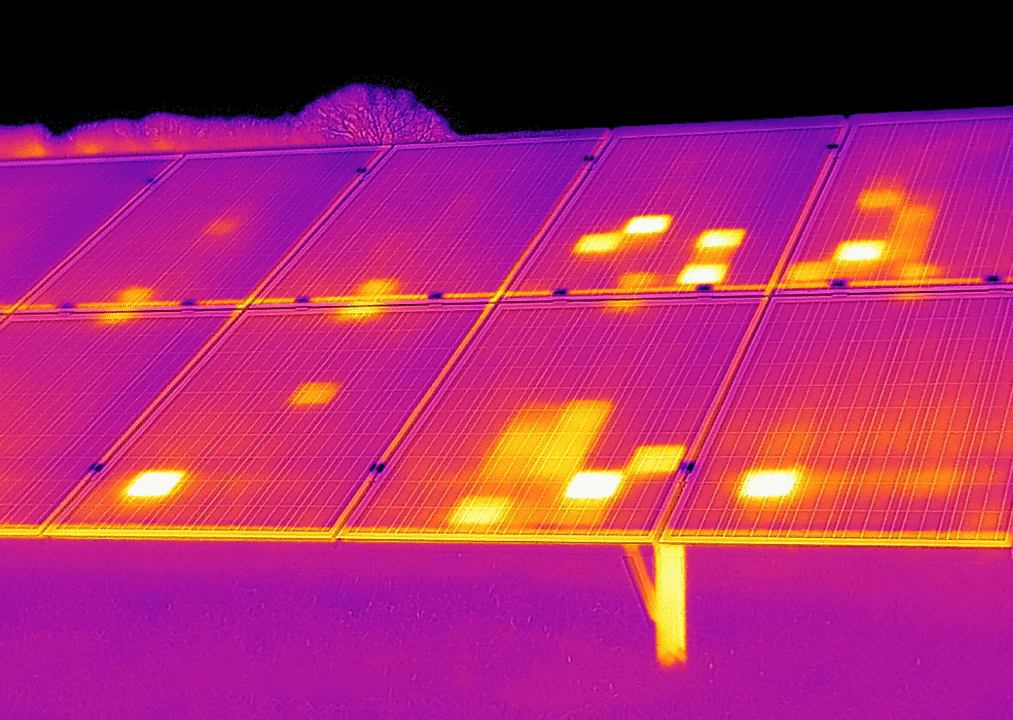

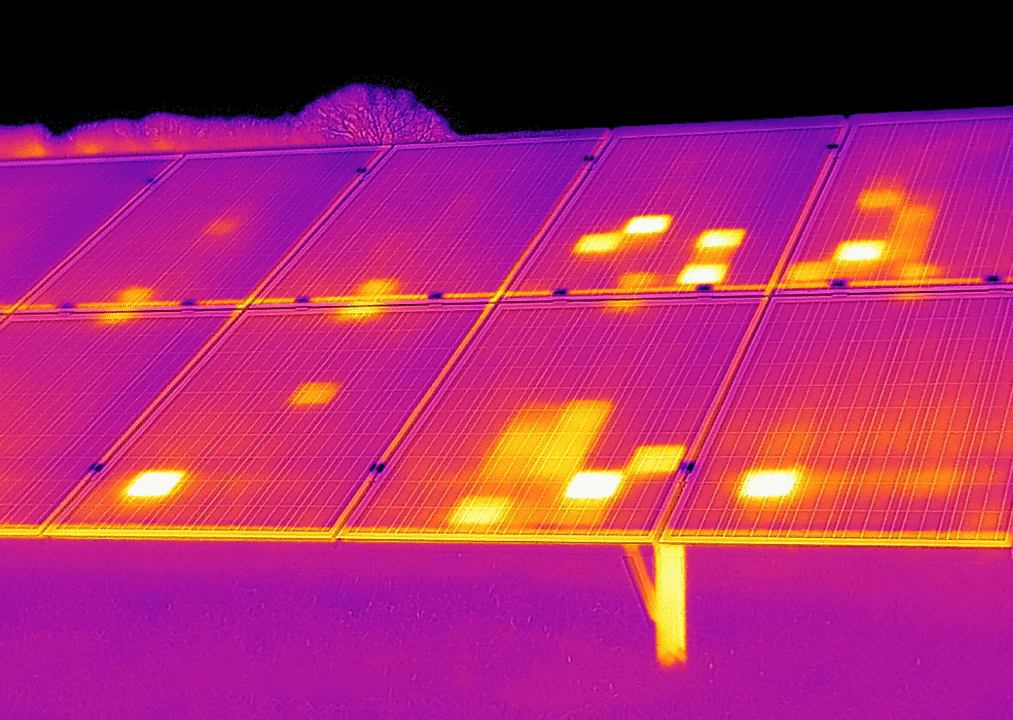

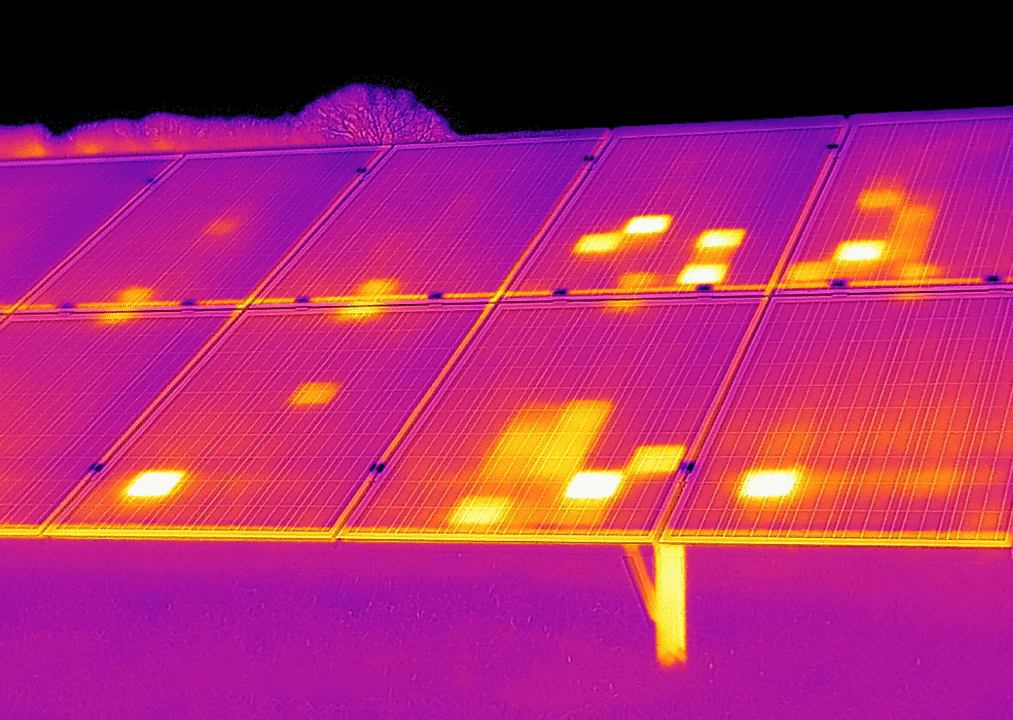

Commercial installations use infrared camera to visually inspect each panel for hotspots caused by an individual cell getting weak. Large utility-scale installations do the survey with drones.

Modern residential installations now use microinverters. Each panel is fitted with its own inverter, and the trunk is now AC instead of DC. This eliminates the hazard of DC arcing. And failure of a cell in a panel simply reduces that panel output.

Commercial installations use infrared camera to visually inspect each panel for hotspots caused by an individual cell getting weak. Large utility-scale installations do the survey with drones.

ERD50

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

....

The fires are electrical in nature. It happens when one of the cells in one of a series of panels gets weak, and cannot keep up with the rest. It gets driven into the reverse bias region, up to its breakdown voltage. The weak cell has to dissipate a lot of heat (similar to a Zener diode in reverse bias) and burns up. ...

Impressive videos!

But don't solar calls have reverse protection (back-biased) diodes on them? That should protect against a weak/shaded cell. Though any connection break in the high voltage DC would still be susceptible to arcing as shown in those videos.

I never really thought about this, as I'm thinking in terms of the micro-inverters, which avoid the high voltage DC string and also optimize output of each panel (through MPPT).

-ERD50

Lakewood90712

Thinks s/he gets paid by the post

- Joined

- Jul 21, 2005

- Messages

- 2,223

Hey NW, are the utility operators in AZ still charging us dolts in California to take excess solar generated power off our hands so our statewide grids dont go down from over voltage ?

NW-Bound

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jul 3, 2008

- Messages

- 35,712

... But don't solar calls have reverse protection (back-biased) diodes on them? That should protect against a weak/shaded cell. Though any connection break in the high voltage DC would still be susceptible to arcing as shown in those videos.

I never really thought about this, as I'm thinking in terms of the micro-inverters, which avoid the high voltage DC string and also optimize output of each panel (through MPPT).

-ERD50

A solar panel usually has only 3 bypassing diodes, whether it has 60, 72, or 96 cells. It is not feasible to bypass every single cell.

So, a bypassing diode is wired across as many as 32 cells, and these cells normally produce 16V in series (0.5V per cell). A weak cell is then subject to 16V of reverse bias before the diode would conduct. A string of large panels has a current as high as 10A. That's potentially 160W of power to be dissipated by a weak cell.

A solar cell is like a diode with a huge surface area of several square inches, and it is not possible to expect the breakdown voltage to be uniform over such a large area. A weak spot may break down before the bypassing diode conducts, and the entire 160W is dissipated over a tiny spot. Nothing good comes after this.

And then, a bypassing diode may fail too.

Microinverters are a recent development. I don't know if they are used in large commercial installations.

Last edited:

NW-Bound

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jul 3, 2008

- Messages

- 35,712

Hey NW, are the utility operators in AZ still charging us dolts in California to take excess solar generated power off our hands so our statewide grids dont go down from over voltage ?

I have not heard any more about this. Maybe it has not happened again. Maybe it's good for both power donor and recipient to keep quiet.

ERD50

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

A solar panel usually has only 3 bypassing diodes, whether it has 60, 72, or 96 cells. It is not feasible to bypass every single cell. ...

Thanks. I was thinking the reverse bias protection diode was integrated right into the solar cell, the way you see them on an IC input. I guess that's just not feasible with solar cell production.

-ERD50

ncbill

Thinks s/he gets paid by the post

Residential installations used to be high voltage, of up to 600VDC. Panels are wired in strings of perhaps 10 panels each, which then feed a string converter. Some converters have an electronic arc fault detector to shut down when an intermittent irregular current is detected.

Modern residential installations now use microinverters. Each panel is fitted with its own inverter, and the trunk is now AC instead of DC. This eliminates the hazard of DC arcing. And failure of a cell in a panel simply reduces that panel output.

Commercial installations use infrared camera to visually inspect each panel for hotspots caused by an individual cell getting weak. Large utility-scale installations do the survey with drones.

That must be for grid-tied installs.

Off-grid use multiples of 12VD for obvious reasons...48VDC often recommended given wiring issues with 12VDC.

NW-Bound

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jul 3, 2008

- Messages

- 35,712

For storage batteries, indeed a voltage that is a multiple of 12V is often used, as it is carried over from the traditional lead-acid battery. The low voltage of 12V is only for very small systems, and larger systems usually use a 48V battery.

The internal battery of a Tesla Powerwall is not exposed to the user. They are not limited to using a low voltage, such as the 48V systems that cater to the DIY'ers.

However, the wiring of the solar panels to the charge controller(s) is much cheaper and simplified if the panels are connected in a string, which reduces the number of cables bringing the juice from the panels to the charge controller(s). Voltages from 100V to 200V are often used, and some charge controllers meant for DIY projects will accept up to 600V.

The internal battery of a Tesla Powerwall is not exposed to the user. They are not limited to using a low voltage, such as the 48V systems that cater to the DIY'ers.

However, the wiring of the solar panels to the charge controller(s) is much cheaper and simplified if the panels are connected in a string, which reduces the number of cables bringing the juice from the panels to the charge controller(s). Voltages from 100V to 200V are often used, and some charge controllers meant for DIY projects will accept up to 600V.

Last edited:

Texas Proud

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- May 16, 2005

- Messages

- 17,317

Why is the TX grid isolated?

So they do not have to deal with federal regulations.

ERD50

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

The installation of the panels plus 2xPylon 2.4kWh batteries was £7,500 ($9,375). Additional batteries can be bought for under $1k and easy to self install.

https://zerohomebills.com/product/pylontech-us2000b-plus-2-4-kwh-li-ion-battery-module-48v/

ETA

We currently pay £0.145/kWh for electricity (18c/kWh)

I looked up PylonTech. It is a Chinese company that makes its own LFP (lithium ferrophosphate) as well as attached electronics. I did not hear about this company, but saw that they are partnered with Victron Energy who is a premier Dutch maker of inverters for the RV and marine segments.

The price of £700 for a 2.4 kWh battery is US$353/kWh. That's the best price I have seen for a packaged battery with an integrated BMS (battery management system). ....

I guess I don't quite see the economics of this battery. I assume it is to time-shift your usage, and store during low rate hours, and use during high rate hours; or to store and use solar energy rather than sell it back to the utility (assuming they pay you less for it than what they charge, or you over-produce and they are net-zero)?

According to my first round of calcs, you need about a $0.10~$0.12/kWh delta in those prices to break even. That assumes the 80% DOD, done 365 days per year, for 16.44 years (6000 cycles). I ignored round-trip storage losses, so a bit higher delta needed.

I'm assuming the battery is worth nothing after 6,000 cycles/16.44 years, and a 2%-4% opportunity cost on your investment for that $0.10~$0.12 range. Is a higher kWh delta feasible? And/or my calcs are too far off?

-ERD50

Rustic23

Thinks s/he gets paid by the post

So they do not have to deal with federal regulations.

This appears to be the right answer:

https://www.texastribune.org/2011/02/08/texplainer-why-does-texas-have-its-own-power-grid/

Article has a nice map showing the grid.

NW-Bound

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jul 3, 2008

- Messages

- 35,712

I guess I don't quite see the economics of this battery. I assume it is to time-shift your usage, and store during low rate hours, and use during high rate hours; or to store and use solar energy rather than sell it back to the utility (assuming they pay you less for it than what they charge, or you over-produce and they are net-zero)?

According to my first round of calcs, you need about a $0.10~$0.12/kWh delta in those prices to break even. That assumes the 80% DOD, done 365 days per year, for 16.44 years (6000 cycles). I ignored round-trip storage losses, so a bit higher delta needed.

I'm assuming the battery is worth nothing after 6,000 cycles/16.44 years, and a 2%-4% opportunity cost on your investment for that $0.10~$0.12 range. Is a higher kWh delta feasible? And/or my calcs are too far off?

-ERD50

A lot depends on specific circumstances.

For years, I subscribe to the "Time of Use" rate, which currently charges 24c/kWh for 2PM-8PM, but only 7c for other times. If I use a "Flat" rate, then it is about 12c. Note that in the winter, the peak period is different, and the price differential is less.

Arbitraging between the two rates using the battery would get me 17c already. If the source of the power is solar, then I get the whole 24c.

People in California also pay a very high rate, and it may work out for them similarly.

NW-Bound

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jul 3, 2008

- Messages

- 35,712

It used to be that people with a grid-tied system could dump their excess solar power into the grid at midday to get 24c/kWh, then get credit to draw out the power at 7PM at the same rate.

This obviously is not fair, once we have seen the "duck curve" showing how there's solar power out the wazoo in midday, but a painful shortage in the early evening.

And so, my local utility now buys and sells at wholesale prices. They also charge for the grid infrastructure, because without it you cannot buy/sell power to/from them.

This obviously is not fair, once we have seen the "duck curve" showing how there's solar power out the wazoo in midday, but a painful shortage in the early evening.

And so, my local utility now buys and sells at wholesale prices. They also charge for the grid infrastructure, because without it you cannot buy/sell power to/from them.

Last edited: