easysurfer

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jun 11, 2008

- Messages

- 13,155

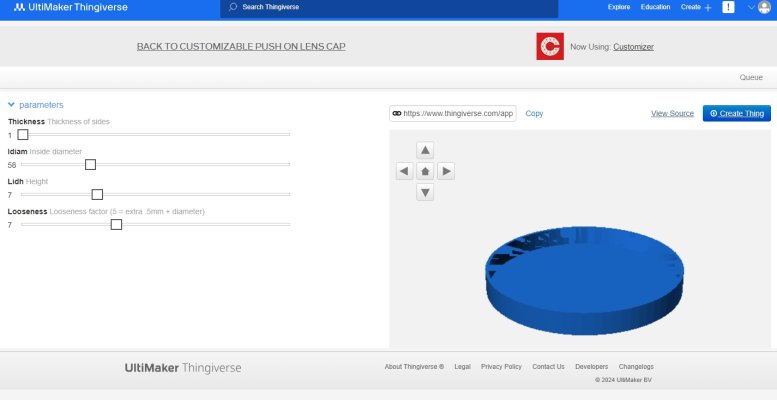

Sometimes while going about my daily business, I think, would be nice is a simple part was 3D printed to solve a need. Such is the case recently.

I bought this old point and shoot camera (as is, parts not working category from ebay) that works fine except the built in lens protector broke off and is not replaceable. So, I ordered (an overly priced one) lens cap. But that didn't fit. Off by maybe a mm or two. So I returned that.

Then I got to thinking, if I had a 3D printer, maybe there's a file out there of the right size I need.

After finding there wasn't one, I thought maybe I could design my own. That's where I temporarily hit a wall. I've discovered that 3D CAD software programs, though several are free and no matter how "easy" the descriptions and tutorials claim are not easy.

Over the past couple of days I must have tried about 6 different programs and end up struggling with just trying to make a design of a simple lens cap .

.

Do most folks who have 3D printers make their own designs? Or do they use to print out ready made ones?

I bought this old point and shoot camera (as is, parts not working category from ebay) that works fine except the built in lens protector broke off and is not replaceable. So, I ordered (an overly priced one) lens cap. But that didn't fit. Off by maybe a mm or two. So I returned that.

Then I got to thinking, if I had a 3D printer, maybe there's a file out there of the right size I need.

After finding there wasn't one, I thought maybe I could design my own. That's where I temporarily hit a wall. I've discovered that 3D CAD software programs, though several are free and no matter how "easy" the descriptions and tutorials claim are not easy.

Over the past couple of days I must have tried about 6 different programs and end up struggling with just trying to make a design of a simple lens cap

.

.Do most folks who have 3D printers make their own designs? Or do they use to print out ready made ones?

Last edited: