deadshort, wow, amazingly good questions!

The freshwater tank (37 gallons) is below the gray water tank (37 gallons) and both are under the sink area as you noted. There is a table of 1-1/8" thick plywood between the tanks on oak legs

For poop we decided to go with a Thetford cassette toilet, popular in Europe/Australia. It isn't your standard camping toilet but rather looks more like a traditional toilet with a 6 gallon cassette you remove from a hatch outside the camper. We purchased an extra 6 gallon cassette for extended stays. This is probably the show stopper for some people as they would want a larger pump out tank, but the cassette is easier to dump and isn't messy at all.

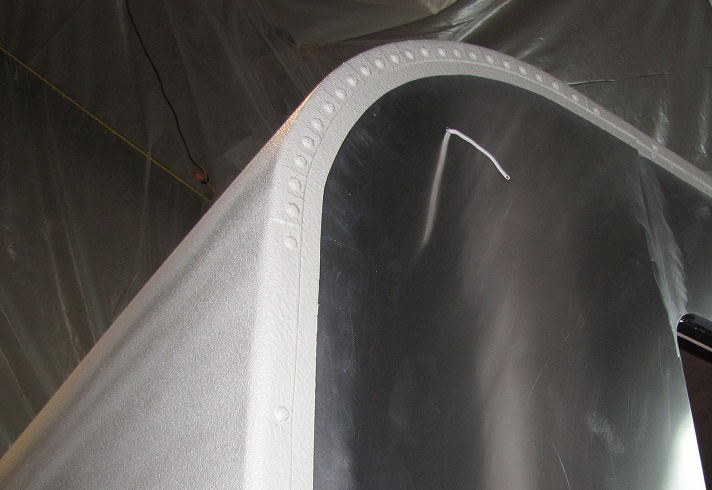

For air conditioning we have a 6000 BTU ultra small wall mount unit. I built an aluminum duct system to allow it to be totally inside the camper and just a flush mount air grill on the outside of the camper (on the side). It has an aluminum pan to catch condensation and a drain system. Last summer it cooled the well insulated camper down from 90F to 70F in under 45 min. It draws about 450 to 500 watts.

We do have a Honda EU2000 portable gen which we carry but also have Lifeline AGM batteries for use with the 4kW inverter. It is my hope that gen use will be minimal in most areas. The garage pod has a separate smaller pure sine inverter/charger and a single Lifeline 125AH battery. The two units connect with a 115VAC cable (socketed and fused) and the main pod charges the garage pod when excess power is available from either solar or gen. In this manner the garage pod can be offloaded and still have power (sparingly) for the interior LED lights and the dual winch system which raises/lowers the ramp door.

Bang on correct about 40" high bed...amazing. Yes, it is a little bit wobbly on the jacks but not unsafe. I would probably NOT unload in high winds

and I would not leave it at max height for longer than needed to get the truck out from under it. The mounts are sturdy, it is just the extended jack legs that have a little play in them.

Here are a couple more pics that show these answers: