I'm mostly writing to make others aware of the superglue.baking soda trick.

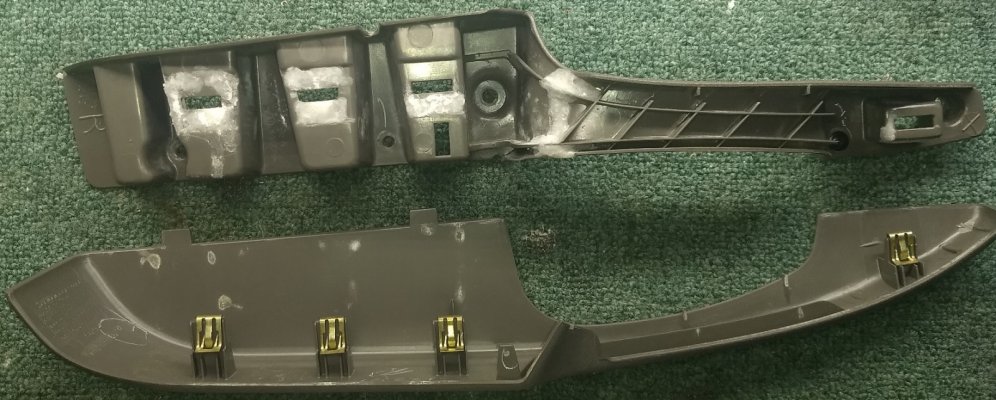

Yesterday, my son pulled our van door closed and the armrest/doorpull came off in his hand. It broke in 6 places, mostly at the clip holders and screw holes. A few of the small broken pieces were missing, but we recover maybe 5 of the 9 pieces.

We started by super gluing the the pieces we had back into position. Then add more super glue in supporting places and sprinkle baking soda on top. I did this many time to make a thicker, stronger support across the cracks. For the missing pieces I just kept repeating, glue, baking soda, over and over until the void was filled. The combination dries hard as a rock, so if you need flexibility, you need to get it elsewhere.

I put the baking soda on a creased sheet of paper so I could dump a large amount on the glue, then just tap it off back onto the creased sheet for reuse. I recommend a thin superglue, it just works better.

There are lots of Youtube videos on this, here are a few.

Here's video to learn from his mistake.

The superglue/baking soda reaction is very quick, it is also exothermic, but localized, so cools quickly.

Some pictures to show some of the repair, all but the small white triangle are internal and can't be seen when assembled. The 1st pic shows the whole arm rest with some of the repairs the rectangular holes where broken out in pieces, and the repair in the middle is where arm rest was cracked into two pieces. The 2nd pic shows the repair of that crack and the 3rd pic is the otherside of that repaired crack with a fill in for a missing piece.

Hope that helps your next repair.