You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Souschef's switch engine project

- Thread starter Souschef

- Start date

Souschef

Thinks s/he gets paid by the post

Today we drilled, and tapped the left side of the bell housing. We installed the eye bolts and the 1/2 inch bolts between them.

That completes the preliminary work. The next task is to get the diesel running. Here is the plan:

1. Install pushrods and injectors

2. Adjust rocker arms to factory specifications

3. Replace rocker arm cover gaskets and reinstall covers

4. Reinstall starter

5. Inspect all rubber hoses and replace as necessary

6. Drain and refill radiator

7. Drain crankcase and replace with 5 gallons of oil

8. Replace air, oil, fuel and fuel/water filters

9. Remove the belt driving the alternator

10. Connect batteries to starter

11. Cross our fingers

That completes the preliminary work. The next task is to get the diesel running. Here is the plan:

1. Install pushrods and injectors

2. Adjust rocker arms to factory specifications

3. Replace rocker arm cover gaskets and reinstall covers

4. Reinstall starter

5. Inspect all rubber hoses and replace as necessary

6. Drain and refill radiator

7. Drain crankcase and replace with 5 gallons of oil

8. Replace air, oil, fuel and fuel/water filters

9. Remove the belt driving the alternator

10. Connect batteries to starter

11. Cross our fingers

Attachments

CRLLS

Thinks s/he gets paid by the post

Souschef, That is an interesting fix. From the looks of it, the eyebolts are made of formed steel, not cast. Generally that is a very soft and weak grade of steel. It will easily bend in use. If so, I would weld the end of the loop to the shank. I would have also added a spacer sleeve cut to fit each bolt between the 2 eyebolts to make it stronger.

Actually, I would have taken some steel straps, maybe 1/4 to 3/8" thick across the break instead of the eyebolts. Thinking more about what you did, I think you used the eyebolts as a tool to pull everything together. You might think about adding the straps between each set of bolts now that things are in place.

Nice work!

Actually, I would have taken some steel straps, maybe 1/4 to 3/8" thick across the break instead of the eyebolts. Thinking more about what you did, I think you used the eyebolts as a tool to pull everything together. You might think about adding the straps between each set of bolts now that things are in place.

Nice work!

ERD50

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

Souschef, That is an interesting fix. From the looks of it, the eyebolts are made of formed steel, not cast. Generally that is a very soft and weak grade of steel. It will easily bend in use. If so, I would weld the end of the loop to the shank. I would have also added a spacer sleeve cut to fit each bolt between the 2 eyebolts to make it stronger.

Actually, I would have taken some steel straps, maybe 1/4 to 3/8" thick across the break instead of the eyebolts. Thinking more about what you did, I think you used the eyebolts as a tool to pull everything together. You might think about adding the straps between each set of bolts now that things are in place.

Nice work!

Yes, I see your concern that the eyebolts are probably pretty soft metal, and may bend over time and vibration. Though I'm sure Souschef will be monitoring that crack for any signs of it growing. It may be just fine for the loads it will see. Hard to say.

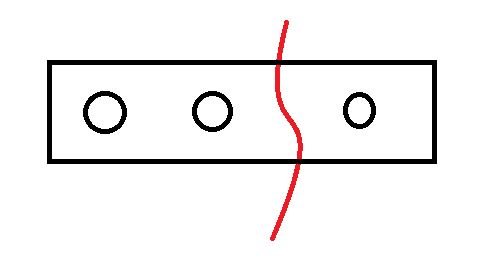

But what might be better, if this doesn't hold up, is something like the drawing I'm showing here. In place of eyebolts, he could use a pair of hardened pins/bolts, with a hard steel plate and hardened bolt (or 2-3 bolts, going on each side of the pins) to tie it all together.

-ERD50

Attachments

Souschef

Thinks s/he gets paid by the post

Thank you both for your suggestions. We will be monitoring our fix after we get the engine running.

The real key to the repair was the addition of steel supports under the rear of the engine to remove the load from the bell housing.

The real key to the repair was the addition of steel supports under the rear of the engine to remove the load from the bell housing.

Souschef

Thinks s/he gets paid by the post

Thank you both for your suggestions. We will be monitoring our fix after we get the engine running.

The real key to the repair was the addition of steel supports under the rear of the engine to remove the load from the bell housing.

The real key to the repair was the addition of steel supports under the rear of the engine to remove the load from the bell housing.

CRLLS

Thinks s/he gets paid by the post

Yes, I see your concern that the eyebolts are probably pretty soft metal, and may bend over time and vibration. Though I'm sure Souschef will be monitoring that crack for any signs of it growing. It may be just fine for the loads it will see. Hard to say.

But what might be better, if this doesn't hold up, is something like the drawing I'm showing here. In place of eyebolts, he could use a pair of hardened pins/bolts, with a hard steel plate and hardened bolt (or 2-3 bolts, going on each side of the pins) to tie it all together.

-ERD50

ERD50, if you look closely, some of the eyebolts are already bent quite significantly; perhaps as much as the diameter of the eye material itself. That is what concerns me. Your hardened pins are a good idea. It does fall short of any rotational retention against torque, as does souschef's original and my plan to add a sleeve.

The added rear engine support is a big step to removing the stress but doesn't remove the torque stress.

An easy solution is to replace the eyebolts with a plate with 3 holes. These can be individually matched to the holes already drilled and tapped. Simply add 1 more tapped hole per splice. That should control the torque between the engine and generator. I would also suggest using Grade 8 bolts. Easy to do now, or wait to see if it fails again and do it then. Just some thoughts.

I am following every post that you make souschef. I love seeing old equipment back to life. BTW, my father and grandfather were both in the railroading business.

Attachments

Olbidness

Recycles dryer sheets

I've got extensive experience with large engines primarily Fairbanks Morse 8 1/8 OP's. But also with FM DLA, Pielsticks, . Love to see the old iron being restored. Keep the pictures and progress updated please.Love it!

Souschef

Thinks s/he gets paid by the post

Thank you for your encouragement. We have done all the preliminary work to get the engine going. I just ordered a new filter for the air cleaner.. We have some reassembly work to do, then start with reinstalling the injectors.I've got extensive experience with large engines primarily Fairbanks Morse 8 1/8 OP's. But also with FM DLA, Pielsticks, . Love to see the old iron being restored. Keep the pictures and progress updated please.Love it!

Souschef

Thinks s/he gets paid by the post

Thisis where we are now, and below are the tasks we hope to do this month:

GETTING THE ENGINE RUNNING

1. Install pushrods and injectors

2. Adjust rocker arms to factory specifications

3. Replace rocker arm cover gaskets and reinstall covers

4. Reinstall starter

5. Inspect all rubber hoses and replace as necessary

6. Drain and refill radiator

7. Drain crankcase and replace with 5 gallons of oil

8. Reinstall air cleaner

9. Replace air, oil, fuel and fuel/water filters

10. Remove the belt driving the alternator

11. Connect batteries to starter

12. Cross our fingers

Once we get the engine running, we can then deal with the generator, traction motor, air compressor and all the relays and controls.

We will need a third battery to operate the relays and controls. We have been assured that the higher voltage is OK.

We also need to get the compressor checked out as well as the control valves. We will have the air gauge calibrated so we can check out the valves. We would like to get the brakes working before trying to move the engine with the generator. We want to have a positive way to stop the engine after we get it going!

GETTING THE ENGINE RUNNING

1. Install pushrods and injectors

2. Adjust rocker arms to factory specifications

3. Replace rocker arm cover gaskets and reinstall covers

4. Reinstall starter

5. Inspect all rubber hoses and replace as necessary

6. Drain and refill radiator

7. Drain crankcase and replace with 5 gallons of oil

8. Reinstall air cleaner

9. Replace air, oil, fuel and fuel/water filters

10. Remove the belt driving the alternator

11. Connect batteries to starter

12. Cross our fingers

Once we get the engine running, we can then deal with the generator, traction motor, air compressor and all the relays and controls.

We will need a third battery to operate the relays and controls. We have been assured that the higher voltage is OK.

We also need to get the compressor checked out as well as the control valves. We will have the air gauge calibrated so we can check out the valves. We would like to get the brakes working before trying to move the engine with the generator. We want to have a positive way to stop the engine after we get it going!

CoolRich59

Thinks s/he gets paid by the post

Looking forward to this update.Once we get the engine running ...

Will you be able to post a video?

Souschef

Thinks s/he gets paid by the post

I hope we can. I just bought two batteries and a big 1-3/4 inch wrench to turn the engine over so we can set the injectors.Looking forward to this update.

Will you be able to post a video?

Our hope is to get the engine moving by the end of the month.

Souschef

Thinks s/he gets paid by the post

It finally cooled off enough to start back on the engine. My genius wife suggeted we use our beach umbrella to provide some shade while we worked. It really helped.

We got out the injectors and the pushrods and all the attaching hardware and installed them. Much to our dismay, we found that the injector pushrods were missing!

I called the company that repaired them, and told them to find them. If not we will have to by new ones.

We got out the injectors and the pushrods and all the attaching hardware and installed them. Much to our dismay, we found that the injector pushrods were missing!

I called the company that repaired them, and told them to find them. If not we will have to by new ones.

Attachments

Hermit

Thinks s/he gets paid by the post

Wouldn't that be "if not, THEY will have to buy new ones?"It finally cooled off enough to start back on the engine. My genius wife suggeted we use our beach umbrella to provide some shade while we worked. It really helped.

We got out the injectors and the pushrods and all the attaching hardware and installed them. Much to our dismay, we found that the injector pushrods were missing!

I called the company that repaired them, and told them to find them. If not we will have to by new ones.

Souschef

Thinks s/he gets paid by the post

I got an e-mail from the company saying they were going to ship the parts todayWouldn't that be "if not, THEY will have to buy new ones?"

Souschef

Thinks s/he gets paid by the post

The parts arrived today!!I got an e-mail from the company saying they were going to ship the parts today

Souschef

Thinks s/he gets paid by the post

Installed the injector links and turned the engine. I wire brushed the pulley and found the other 2 timing marks.

I bought a push button to hook up to the starter. Unfortunately, I thought I had a lug crimper but did not. I will do it another day.

We are getting closer to the day we will try to start the engine

I bought a push button to hook up to the starter. Unfortunately, I thought I had a lug crimper but did not. I will do it another day.

We are getting closer to the day we will try to start the engine

Hermit

Thinks s/he gets paid by the post

Installed the injector links and turned the engine. I wire brushed the pulley and found the other 2 timing marks.

I bought a push button to hook up to the starter. Unfortunately, I thought I had a lug crimper but did not. I will do it another day.

We are getting closer to the day we will try to start the engine

Going slow and getting everything as right as you can is probably the best approach. Good luck when it is time to get it started!

ERD50

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

Going slow and getting everything as right as you can is probably the best approach. Good luck when it is time to get it started!

+1

I stay subscribed to this thread, I feel like I'm living through Souschef's adventure!

Might get me motivated to make a visit to the nearby Union, IL RR museum, haven't been there in decades.

I read recently that Rudolph Diesel first experimented with coal dust as a fuel, but the engine exploded! I've bee trying to find out how they made the fuel injectors in those days. Seems like so much precision, and such a harsh environment, subjected to the combustion - how did they do it back then?

-ERD50

Last edited:

CoolRich59

Thinks s/he gets paid by the post

+

Might get me motivated to make a visit to the nearby Union, IL RR museum, haven't been there in decades.

-ERD50

ERD50, I haven't been to the museum (even though it's not that far from me), but you might also like the Railroad Park out in Rochelle. It is the crossroads of two major rail lines (the Union Pacific and the Burlington Northern).

Approximately 80 trains a day pass through here. I took a drive out there last Spring. In the hour I was there, 7 trains came through.

I plan on going back with my grandson.

Souschef

Thinks s/he gets paid by the post

Finally

We installed the batteries and the starter. We also connected the pushbutton to the starter solenoid. We pushed the button, and the engine turned over easily! SUCCESS!

We installed the batteries and the starter. We also connected the pushbutton to the starter solenoid. We pushed the button, and the engine turned over easily! SUCCESS!

Below are the before and after photos of the battery box and starter

Below are the before and after photos of the battery box and starter

Attachments

Hermit

Thinks s/he gets paid by the post

We installed the batteries and the starter. We also connected the pushbutton to the starter solenoid. We pushed the button, and the engine turned over easily! SUCCESS!

Below are the before and after photos of the battery box and starter

Those are some big, honking batteries! Let us know when the big day will be.

Souschef

Thinks s/he gets paid by the post

Today was a day of utter frustration. First we replaced the fuel/water filter only to discover that the new filter had different size threads on the than the old filter.. After being unsuccessful in locating adapters, we drained the old filter and reinstalled it. We then took the filter element out of the new filter and put it in the old filter.

[FONT="]Next we removed the fuel filter by unscrewing it with the help of a pipe wrench. We tried installing the new filter only to discover that, even though it was the same part number, it was longer. We ended up removing the mounting bracket to screw the new filter in.[/FONT]

[FONT="]Next we removed the fuel filter by unscrewing it with the help of a pipe wrench. We tried installing the new filter only to discover that, even though it was the same part number, it was longer. We ended up removing the mounting bracket to screw the new filter in.[/FONT]

Souschef

Thinks s/he gets paid by the post

Today was a good day. Yesterday, in anticipation of the engine running, I went out with a meter and checked all the fuses, and they were all good. Also, the voltmeter on the panel registered 24 volts.

We spent today adjusting all the injectors, then replaced the air cleaner filter and installed the air cleaner.

We turned the engine over with the starter, and it sounded anxious to run. As a side note, the two headlights on the engine also lit!

When we attempt to start the engine, we will make a video of it and post it.

We spent today adjusting all the injectors, then replaced the air cleaner filter and installed the air cleaner.

We turned the engine over with the starter, and it sounded anxious to run. As a side note, the two headlights on the engine also lit!

When we attempt to start the engine, we will make a video of it and post it.

- Joined

- Nov 27, 2014

- Messages

- 9,254

Very much looking forward to seeing run. Will the switch move, or is that another thread?

Similar threads

- Replies

- 15

- Views

- 920

- Replies

- 4

- Views

- 682

- Replies

- 30

- Views

- 3K