This is cross-posted (and a bit amplified) from my other thread about "Dishwasher leaking: Fix or Replace?" as I"m trying to get things buttoned-up thsi afternoon.

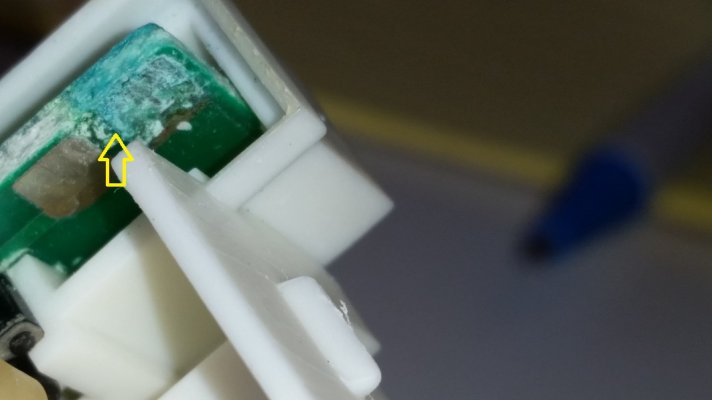

In the process of reassembling everything, I noticed that there's a lot of corrosion on the electrical connector that was attached to the circuit board on the base of the diverter valve. This is the general area where the water was leaking, so this corrosion developed over time.

I am attaching a photo of the OLD diverter valve circuit board to give you an idea of the level of corrosion. (BTW, there is a completely new diverter valve on the assembly that I am installing, so this is just to demonstrate the level of corrosion.)

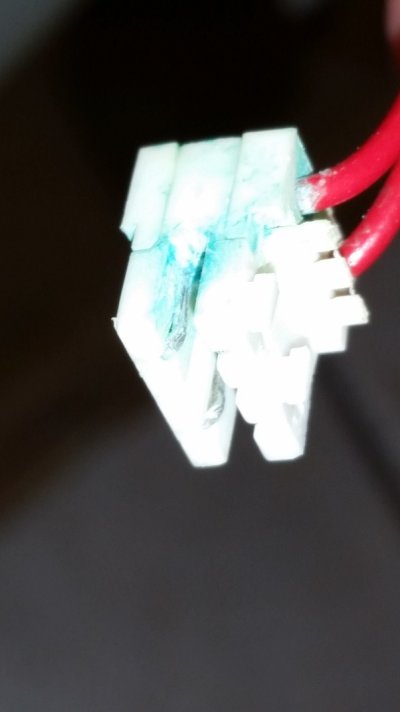

I am hoping to reuse the old electrical connector. (As it is small and convoluted, the corrosion is difficult to see....which is why I am not attaching a photo of it.)

I tried mechanically scraping the connector with a knife, hoping to expose some clean metal to make a good contact.

My concerns are twofold -- 1) will this scraping expose enough metal in the connector to make a good contact when I reassemble things? and 2) will that electrical contact remain over time, or will the remaining bits of corrosion on the connector keep corroding and eventually break the contact?

Is there some way to clean the corrosion off the CONNECTOR easily? I saw a video online where they used 2 solutions: one is a super-saturated table salt & vinegar solution to remove the oxidation/corrosion, followed by a baking soda & water solution to neutralize everything from the first solution.

Does this work? or Am I better served by doing something else to get rid of the corrosion short- and long-term(and what would that be)?

Would spraying the connection with WD-40 be of any use?

(I have limited tools and supplies here, fwiw.)

omni

In the process of reassembling everything, I noticed that there's a lot of corrosion on the electrical connector that was attached to the circuit board on the base of the diverter valve. This is the general area where the water was leaking, so this corrosion developed over time.

I am attaching a photo of the OLD diverter valve circuit board to give you an idea of the level of corrosion. (BTW, there is a completely new diverter valve on the assembly that I am installing, so this is just to demonstrate the level of corrosion.)

I am hoping to reuse the old electrical connector. (As it is small and convoluted, the corrosion is difficult to see....which is why I am not attaching a photo of it.)

I tried mechanically scraping the connector with a knife, hoping to expose some clean metal to make a good contact.

My concerns are twofold -- 1) will this scraping expose enough metal in the connector to make a good contact when I reassemble things? and 2) will that electrical contact remain over time, or will the remaining bits of corrosion on the connector keep corroding and eventually break the contact?

Is there some way to clean the corrosion off the CONNECTOR easily? I saw a video online where they used 2 solutions: one is a super-saturated table salt & vinegar solution to remove the oxidation/corrosion, followed by a baking soda & water solution to neutralize everything from the first solution.

Would spraying the connection with WD-40 be of any use?

(I have limited tools and supplies here, fwiw.)

omni