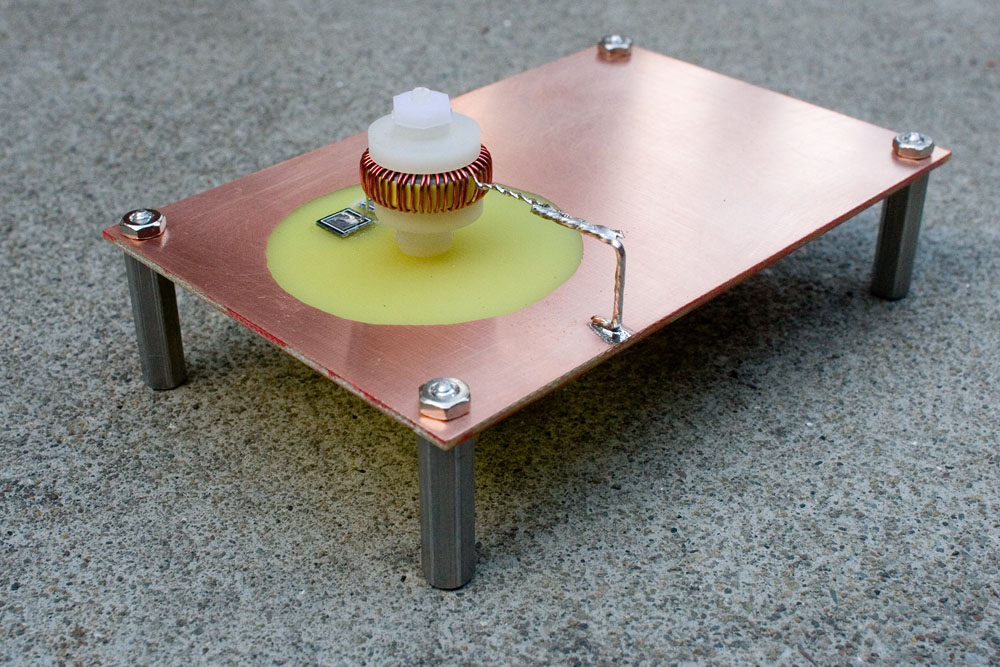

Here's what I finished today: rewinding a big and mean toroid inductor to use in my home-brew MPPT controller (the thinggy that sits between a solar panel and the RV battery bank). There might be 1.5 lb of ferrite in each of the 3" doughnuts in the photo below.

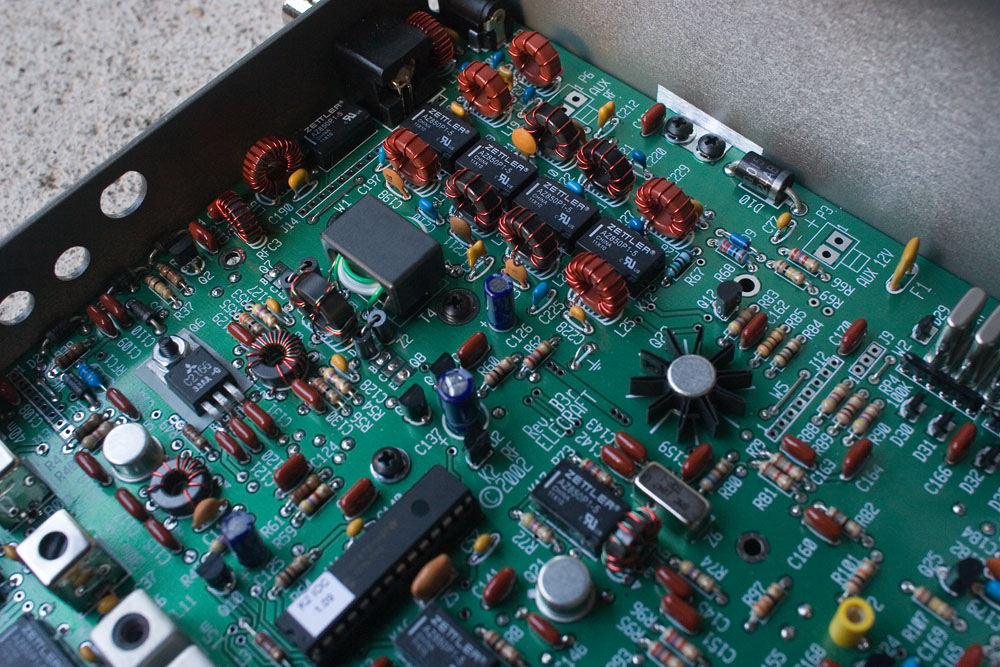

I bought these surplus toroids a while back, and they looked like they were for some industrial applications. They would be expensive and difficult to get new. Typical DC/DC converters would use smaller inductors to save cost, but they would need to run at higher switching frequencies. High-frequency converters are more tricky to build for a one-off design. My home-brew design will use a lower frequency of 100KHz, and this big toroid works out great.

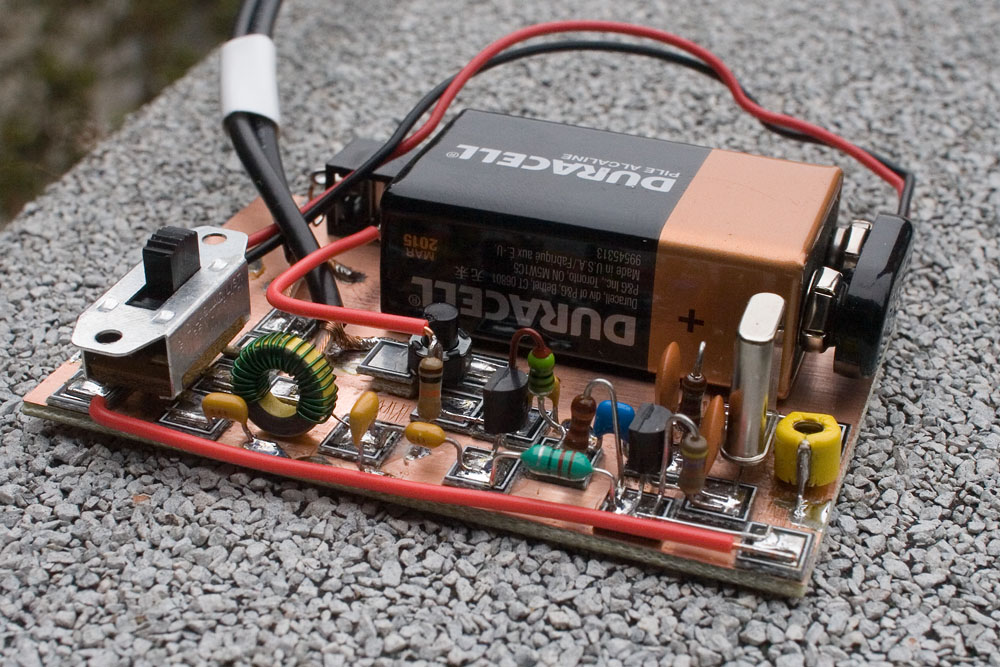

The problem was that its value of 1.1mH was higher than necessary and it had an resistance of 100milliOhms. So, I unwound it, cut the copper wire in 3, and rewound it with a trifilar winding. Ideally, reducing the number of turns to 1/3 and tripling up the wire would result in 1/9 the inductance and also 1/9 the resistance. Due to a bit of lead length at the ends, I ended up with a ratio of 1/10.

At a charging current in excess of 15A, the loss due to the initial coil would have been greater than 22.5W, or 1/10 the max output of the panel. It is now 2.25W, a much more palatable number.

It took me a couple of hours, because the copper wire was 16-gauge and quite stiff. It has been a long time since I wound some inductors or transformers by hand. It was what I did as a teenager, who had more time than money. Now, as a semi-retired geezer, I am reviving old activities. I am not quite sure if that is good or bad. All this work instead of spending a few hundred bucks to buy one off-the-shelf like everyone else! But then, I have always been a geek. Maybe I should just go back to work.