Mini Split Fan Motor Replacement

After just three years, the fan motor in the indoor unit of our Mr Cool mini-split started making a squeaky noise. It sounded like loud crickets chirping all day long.

Not loud, but extremely annoying over time.

I contacted Mr Cool and after a few email exchanges they agreed to send a new motor. "Free" warranty part with $45 shipping. Still, cheaper than new. They also sent a link to a YouTube video on how to replace it.

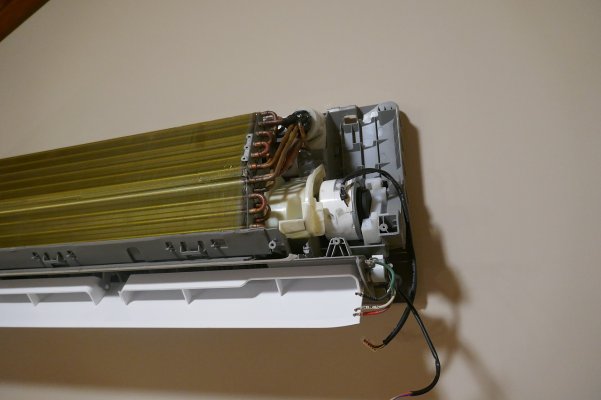

I watched the video 3-4 times, turned off the power, and started pulling ours apart. A bit tricky working 9 feet in the air over the kitchen stove, but manageable. Naturally, our model is different than the one in the video and other than the outer casing nothing else was the same. So it took a long time to figure out how to dismantle the unit to get to the fan. Then it was really tricky getting to the set screw that connected the fan to the motor. I had to have my wife climb up and help hold things while I got that loose.

Eventually I got the old motor out and the new one in. Slowly reassembled everything, turned it on.... and the fan was rubbing. Dang. So it all came apart again and we had to loosen the set screw and carefully adjust the position of the fan so it wouldn't rub.

Reassemble again, almost done, realized I forgot a screw on one of the inside covers. So, disassemble again to fix that. Overall I think I had to take the unit apart about 4-5 times for various reasons. Unfortunately, (as usual) some of the plastic clips on the surround broke off in the process, but once it was all reassembled it all worked nicely with no vibration and no fan noise. Yay!

However, when I turned the unit on the fan worked perfectly, but it wouldn't heat or cool. I feared we had cracked a refrigerant line or something fussing with it so many times. Tired and frustrated I gave up and walked away for an hour or two. I gave it another try later and everything started working again. I don't know why, but very relieved. Maybe the temp sensors were too hot from me handling them. Who knows. I'm just glad it works, and am thankful the squeaking is gone.