.... Also, I have a BIL who is an electrician and he said that he has observed that a number of EEs should not be messing with live electricity... that is not their skill even if they could design it easily...

I agree with the other engineers on that. Electrical codes often deal with safety, and aren't apparent to a EE in terms of whether it works from a schematic viewpoint.

An example came to me - early in my career, someone asked for help - their hallway light wasn't working, the typical "one switch at each end of the hallway, either switch turns the light on/off" arrangement.

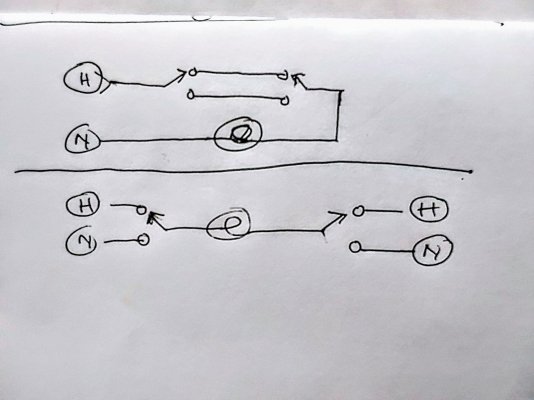

Well, I never really thought about exactly how these things were wired, but it certainly wasn't anything complicated. And oddly, they refer to the switches used as "Three-Way" switches. To an EE, that's not right - these circuits use two identical "Single Pole - Double Throw" (SPDT) switches! What's with "three-way"?

So I sketch out how I figured it is wired, and came up with the bottom drawing. Now, that works perfectly fine. If the left switch it UP (HOT), when the right switch is UP, it will be connected to HOT, and there is no difference in potential, so no current, no light. Flip the right switch DOWN, and now current flows from Left (HOT) to RIGHT (Neutral), etc, etc. That works! And assuming you have a hot and neutral at each end of the hallway, you only need the wires to the light fixture, and you need those anyway. Simple, right?

But, that is *NOT* per code, not the correct way to do it, and for a couple of very good safety reasons. A light fixture should be wired such that the outer screw-thread base part is connected to NEUTRAL (never HOT) - it's easier to come into contact with that, and you could get a lethal shock if you touched it while grounded. The HOT wire goes to the more recessed little contact to the base of the bulb. But my schematic would flip which side of the bulb is HOT, depending on the switch settings. You'd never really know which side was HOT. Considering these are usually fixtures that aren't in easy reach, it would rarely ever cause a problem, but attention to these details is what makes electricity as safe as it is.

Another issue is, you could easily tap into the HOT of one breaker/circuit on one side, and a different circuit/breaker on the other side of the hallway. So you might flip the breaker to work on it, not realizing there are two circuits involved. A GFCI in the panel would be tripped by this configuration.

Look at the upper drawing - Geez, we have to run two wires between those distant switches, AND wires to the bulb socket - seems like a waste, right? But wired this way, one end of the bulb is always connected to NEUTRAL, and one is connected to a (switched) HOT. And, there is only one HOT and one NEUTRAL, no chance of connecting two hots.

NOTE: Code requires a Neutral be run to each box now.

-ERD50