TromboneAl

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Jun 30, 2006

- Messages

- 12,880

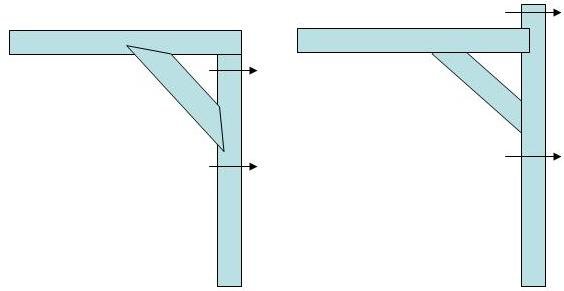

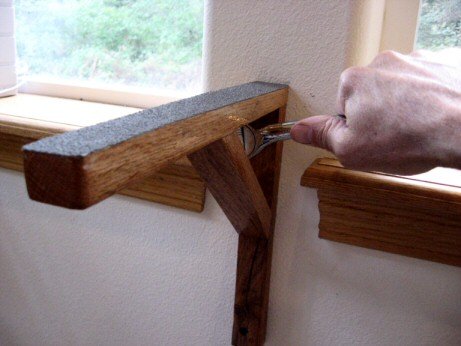

I'm making what is essentially a shelf bracket that will hold my electric piano (38 pounds total), and the current design is like this (the wood is actually nice oak, it will look better when sanded, etc.).

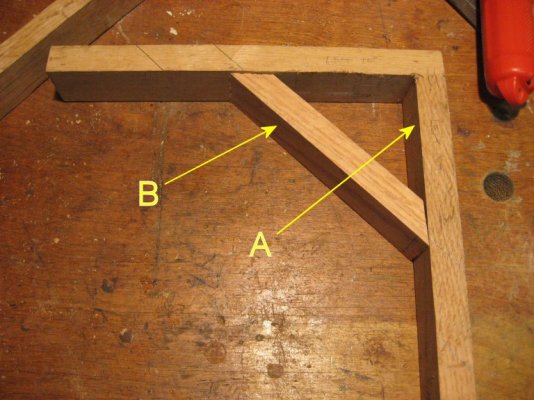

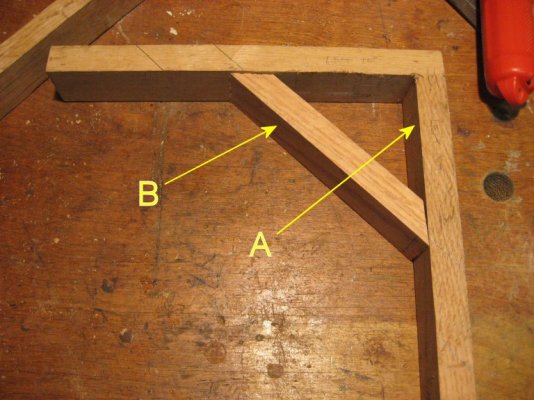

The problem is that I will need to screw it into the wall using a screw at point A. The alternatives I see are:

1. Drill a hole at point B as an access point for the screwdriver.

2. Design it such that I can screw it to the wall and then add the 45 degree brace (less than ideal since screws can't come from the back, and I won't want to use glue).

3. Use an offset screwdriver to drive the screw.

4. Scrap this design and do it another way.

Suggestions?

1. Drill a hole at point B as an access point for the screwdriver.

2. Design it such that I can screw it to the wall and then add the 45 degree brace (less than ideal since screws can't come from the back, and I won't want to use glue).

3. Use an offset screwdriver to drive the screw.

4. Scrap this design and do it another way.

Suggestions?