You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What We're Making

- Thread starter davemartin88

- Start date

Some very talented people in here. I'm not good with tools, I mean, I can use them, just don't enjoy it.

I like to cook, and bake bread.

View attachment 45848

Yum! Looks delicious.

Skyking, Little guy looks perfect and it is a beautiful quilt. My DD wouldn't wait and attended her baby shower too! (many years ago)

skyking1

Thinks s/he gets paid by the post

I knocked together a landing for an office trailer at the job sites. It had a metal staircase but it was awkward to negotiate the door at the top and the guys complained about the hazard.

I put it together using my forklift last night and put it on the truck, and took it down there and unloaded it with the job site forklift.

Then I attached those heavy metal steps to it and finished out the handrail.

I used old lumber from around the yard for the deck and a lot of the lower stuff and picked up a few new 2x6s for the structural.

It was nice to recycle materials. The founder of this company passed away on mother's Day and he was of that era where everything was saved and reused.

I put it together using my forklift last night and put it on the truck, and took it down there and unloaded it with the job site forklift.

Then I attached those heavy metal steps to it and finished out the handrail.

I used old lumber from around the yard for the deck and a lot of the lower stuff and picked up a few new 2x6s for the structural.

It was nice to recycle materials. The founder of this company passed away on mother's Day and he was of that era where everything was saved and reused.

Attachments

Surewhitey

Thinks s/he gets paid by the post

Been gone for a few weeks, but I'm back to w*rk... Client wanted a double sided access to their island with lots of pull outs. They bought a Boo's board top & asked me to build around it.

They regretted buying a flip remodel and are trying to make it their retirement home...

They regretted buying a flip remodel and are trying to make it their retirement home...

Attachments

Surewhitey

Thinks s/he gets paid by the post

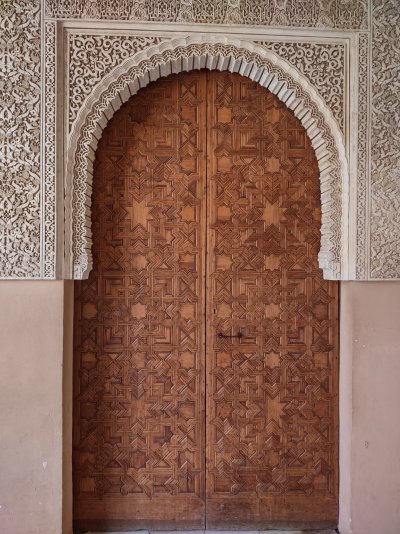

If you ever need to be humbled, visit the Alhambra in Grenada Spain. The amount of artistry is unimaginable in this place that dates back to the 11th century...

Attachments

Ronstar

Moderator Emeritus

Island turned out great Surewhitey!

Ronstar

Moderator Emeritus

Whipped up a hatchet handle for a blade blank that I had. Wood is spalted hackberry.

street

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Nov 30, 2016

- Messages

- 9,543

WOW!!!

You two are amazing talented creative professional craftsmen.

You two are amazing talented creative professional craftsmen.

Surewhitey

Thinks s/he gets paid by the post

Nice work Ronstar. Spalting reminds me of lightning.

Surewhitey

Thinks s/he gets paid by the post

Ronstar

Moderator Emeritus

Looking good Surewhitey!

My son was given a motorized adjustable height desk frame. I was damaged when something fell on it. (Hurricane)

He disassembled it and found a broken threaded piece with triple internal threads.

When I saw this, I thought it was a lost cause, as the part is not available to buy.

The part has a triple internal threads, we wrapped three wires,copper, green and gray to figure that out.

My son drew it in Fusion 360 and used the 3D printer at work to make the part.

It took three iterations, before getting the threads right, but when done the internal threads were amazing.

He also had to make a few other parts, (guides and slides).

So he got it all working well. Now he is building a butcher block style desk top using Sapele wood.

This is his first butcher block build so he made two smaller pieces, a shelf to set his desk top computer on and a slide out shelf. He learned about picking/matching grain on those.

He built a jig to do a a bit of joinery, but still end up hand planing the edges to get a better fit.

Now he has cut and glued a 28" x 66" desk top. He will use Danish oil as the finish. Here's the unfinished desk top.

I think it looks great!

He disassembled it and found a broken threaded piece with triple internal threads.

When I saw this, I thought it was a lost cause, as the part is not available to buy.

The part has a triple internal threads, we wrapped three wires,copper, green and gray to figure that out.

My son drew it in Fusion 360 and used the 3D printer at work to make the part.

It took three iterations, before getting the threads right, but when done the internal threads were amazing.

He also had to make a few other parts, (guides and slides).

So he got it all working well. Now he is building a butcher block style desk top using Sapele wood.

This is his first butcher block build so he made two smaller pieces, a shelf to set his desk top computer on and a slide out shelf. He learned about picking/matching grain on those.

He built a jig to do a a bit of joinery, but still end up hand planing the edges to get a better fit.

Now he has cut and glued a 28" x 66" desk top. He will use Danish oil as the finish. Here's the unfinished desk top.

I think it looks great!

Attachments

Ronstar

Moderator Emeritus

^^^Excellent!! I just got into 3d printing and it’s not easy.

^^^Excellent!! I just got into 3d printing and it’s not easy.

Can I say, the little jerk of mine

His boss told me, "he's really smart!".

Must take after his mother ;-)

Ronstar

Moderator Emeritus

Awesome! I looked into fusion 360, but I’m sticking with sketchup and my limited abilities with it. Fusion 360 is above my skill level.

Programming an Arduino is not an easy task either. Your son is really smart! Reminds me of my nephew. He just dives into software and gets it running in no time.

Programming an Arduino is not an easy task either. Your son is really smart! Reminds me of my nephew. He just dives into software and gets it running in no time.

Awesome! I looked into fusion 360, but I’m sticking with sketchup and my limited abilities with it. Fusion 360 is above my skill level.

Programming an Arduino is not an easy task either. Your son is really smart! Reminds me of my nephew. He just dives into software and gets it running in no time.

Ya, kinda ticks me off, at 68 I just don't pick up things as fast as I used to.

He did use Sketchup for a while, not sure why he moved on, but he has designed several things for 3D printing with Fusion 360 and they come out very good. He is also doing drawings of small projects to build at work and home.

Ronstar

Moderator Emeritus

Whipped up a picture frame for SIL's pup (13 yo golden retriever) out of some leftover barnwood.

Toast

Thinks s/he gets paid by the post

Beautiful frame for a beautiful pup!

street

Give me a museum and I'll fill it. (Picasso) Give me a forum ...

- Joined

- Nov 30, 2016

- Messages

- 9,543

Very nice Ronstar, like always.

skyking1

Thinks s/he gets paid by the post

@surewhitey, that's the joinery I use for my drawer boxes too. I have a dovetail jig but prefer to hammer them out quickly with the dado set.

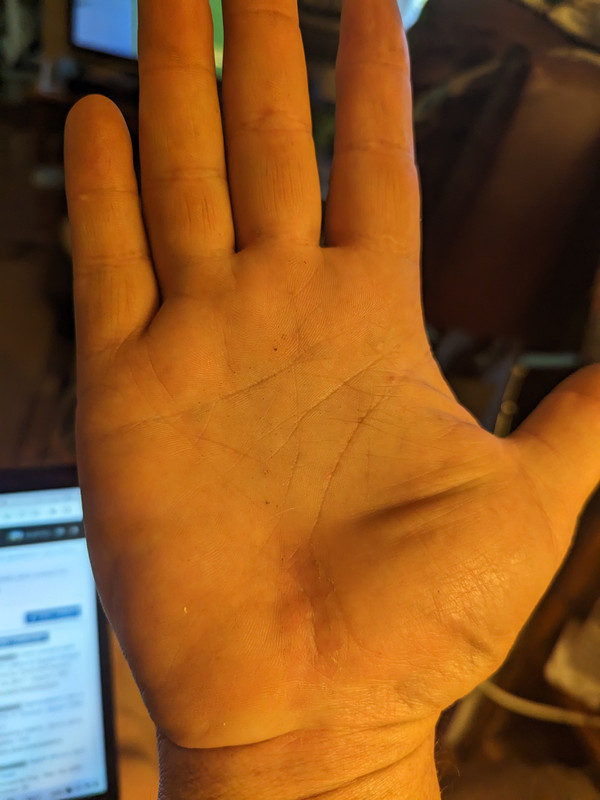

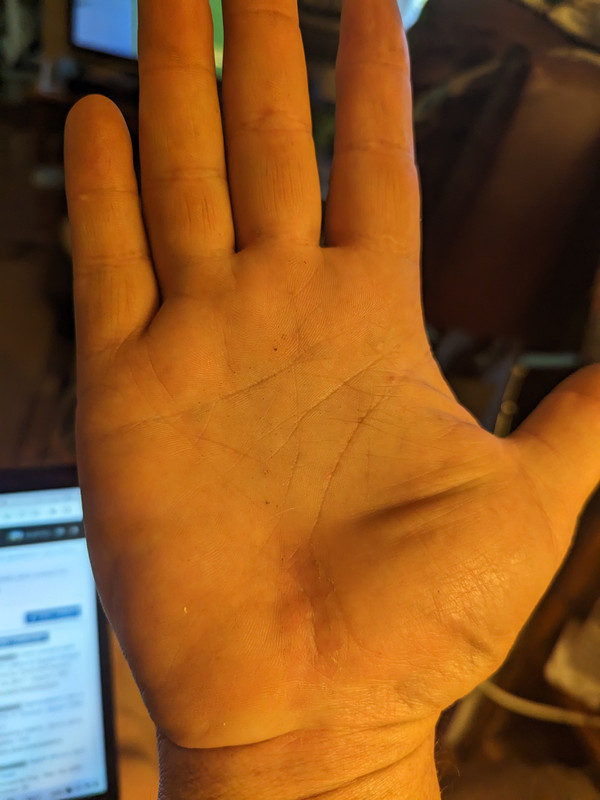

I am working on healing my second carpal tunnel release. It is hard to hold back but I am doing it.

The first one is doing great

I am working on healing my second carpal tunnel release. It is hard to hold back but I am doing it.

The first one is doing great

Surewhitey

Thinks s/he gets paid by the post

Nice grain layout...My son was given a motorized adjustable height desk frame. I was damaged when something fell on it. (Hurricane)

He disassembled it and found a broken threaded piece with triple internal threads.

When I saw this, I thought it was a lost cause, as the part is not available to buy.

The part has a triple internal threads, we wrapped three wires,copper, green and gray to figure that out.

My son drew it in Fusion 360 and used the 3D printer at work to make the part.

It took three iterations, before getting the threads right, but when done the internal threads were amazing.

He also had to make a few other parts, (guides and slides).

So he got it all working well. Now he is building a butcher block style desk top using Sapele wood.

This is his first butcher block build so he made two smaller pieces, a shelf to set his desk top computer on and a slide out shelf. He learned about picking/matching grain on those.

He built a jig to do a a bit of joinery, but still end up hand planing the edges to get a better fit.

Now he has cut and glued a 28" x 66" desk top. He will use Danish oil as the finish. Here's the unfinished desk top.

I think it looks great!

Surewhitey

Thinks s/he gets paid by the post

Whipped up a picture frame for SIL's pup (13 yo golden retriever) out of some leftover barnwood.

You make old barnwood look beautiful...

Surewhitey

Thinks s/he gets paid by the post

@surewhitey, that's the joinery I use for my drawer boxes too. I have a dovetail jig but prefer to hammer them out quickly with the dado set.

I am working on healing my second carpal tunnel release. It is hard to hold back but I am doing it.

The first one is doing great

Yeah, I've always been hesitant to try this for so long. Maybe it's the Kreg Foreman that makes it too easy...

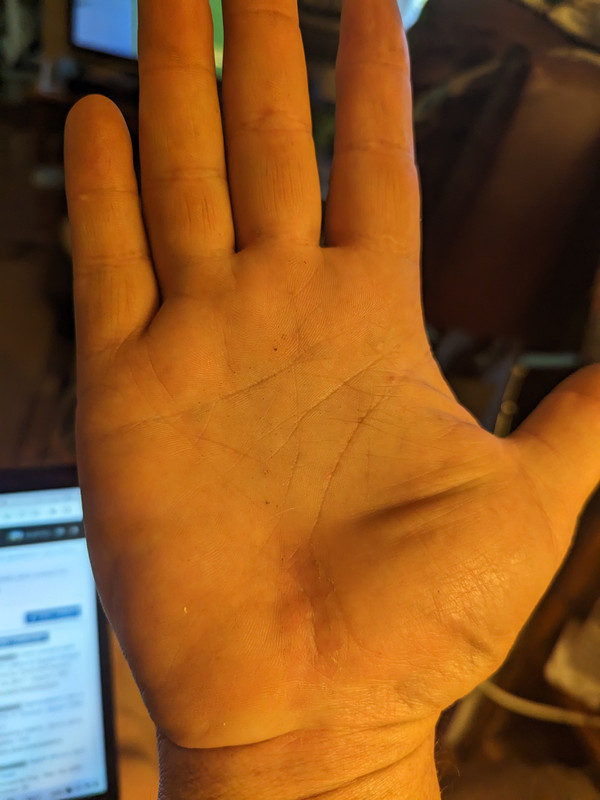

Must be the week for hand injuries. I fell (slipped?) back while pressure washing everything I own & took a chunk out of my inner wrist. Thankfully just a deep bruising besides the slice. I really thought I did some real damage when it first happened...

skyking1

Thinks s/he gets paid by the post

yeah that's not a good look when you see a chunk out where all the tendons and important stuff are.

I used that BB with all the fine plies for boxes, then I ripped thin little veneers of maple to put on top of the edges of the boxes for some quick wood fiber gratification.

The new kitchen is still up in the air for wood choices. Things like hickory, alder, something with a few knots.

I will farm the doors out again and go with a simple panel in frame, possibly a roman ogee inside edge.

Anything but straight shaker. The dust edge drives us mad

I used that BB with all the fine plies for boxes, then I ripped thin little veneers of maple to put on top of the edges of the boxes for some quick wood fiber gratification.

The new kitchen is still up in the air for wood choices. Things like hickory, alder, something with a few knots.

I will farm the doors out again and go with a simple panel in frame, possibly a roman ogee inside edge.

Anything but straight shaker. The dust edge drives us mad

EarlyandLate

Recycles dryer sheets

- Joined

- Jul 15, 2022

- Messages

- 226

Just made a batch (8 half-pints) of wild plum jam. I foraged the plums here in the city less than a mile from my house. Processing the little plums is a lot of work, but the tart-sweet flavor of the jam is worth it!

Similar threads

- Replies

- 67

- Views

- 4K

- Replies

- 14

- Views

- 908

- Replies

- 136

- Views

- 11K