Did you put a finish on the seating in your sauna? What wattage is the heater? How long does it take to bring it up to (what) temperature.?

The company that sold me the kit said that some people choose to put a sealer on the wood, and some people choose not to. They warned against any sealer that wasn't specifically for saunas, I suppose for toxicity. I did not seal the wood. I have been sponging off the bench when I'm done. The heater is 4.5 KW. I have always set the timer to come on when I want to step in, so haven't been waiting for it to heat up. I give it 45 minutes or so to heat up, and it's always been at 155 at head height (but near the ceiling, it's much hotter...like 30 more degrees). I need to get a better feel for how long it takes to heat up, but it's certainly less than 45 minutes. The sauna temp / hygrometer that my daughter bought me takes longer to respond, whereas the electronic indoor/outdoor thermometer responds quickly, and the slow response one always said 155 when I stepped in after 45 minutes. I have the control set to 5 out of 9, and 155 is where it stops.

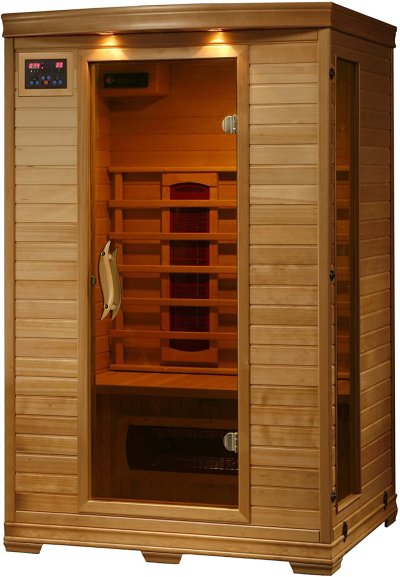

I think the foam panels would work, but you'd need a waterproof floor and some kind of structure to keep it from blowing away, and structure to mount the benches. In my case, the insulation was a small part of the sauna construction. For me, having a pleasing interior, the cedar wood, is a huge part of the experience. As mentioned earlier, you can get stand-alone sauna kits that can just be placed on your patio. That sounds like what you want if you're in a hurry. The stand-alone (whether a kit or from scratch) have more surfaces to worry about. I had 6 (cement floor, four walls and a ceiling, but you'd have another 5 (4 exterior walls and a roof). You'd basically be building a small exterior building, which is more complicated than what I had to do (frame an interior space, insulate, then nail cedar T&G). I've only used it 8 or 10 times so far, but really feel wonderful after I do.

One more thing...I'd warn against going with 110V unless you knew it heated up fast enough for you. I got lazy, didn't want to run a 220 line for my steam generator (not my new sauna, but my old steam generator). As a result, it takes so long to start generating steam that I rarely use it. It doesn't have enough "umph". The sauna, on the other hand, the heater I bought can't be used in a smaller sauna than mine (meaning, it's got plenty of "umph").