Ronstar

Moderator Emeritus

Ronstar,

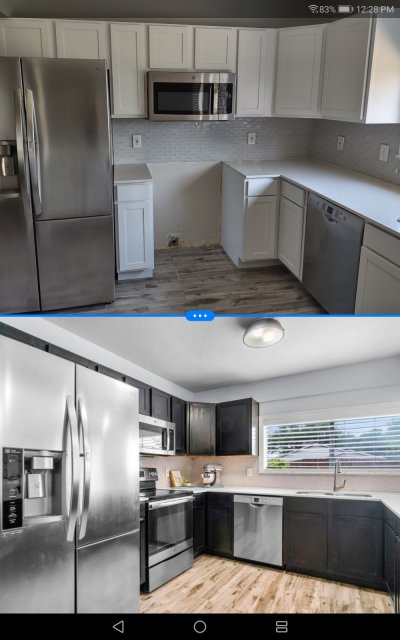

So the details in the handle... Do these go through the blade or just a detail embedded in the wood? Would you mind sharing the blade dealer?

The blanks comes with 5/32" holes in it. And I drilled holes in the handle sides in the same spots. I ordered some 5/32" pins from Woodcraft. Pins go all the way through each a side and the blank.

I got the blank from Etsy dealer Harbour Mercantile.

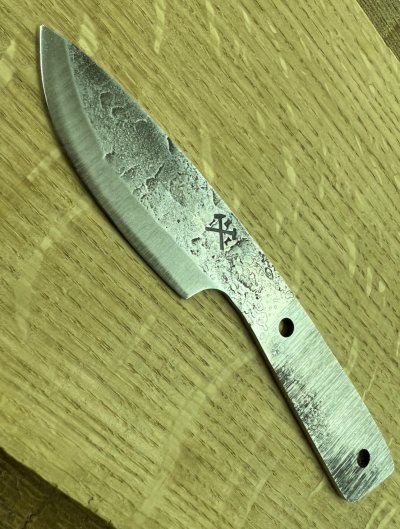

Just ordered one from Indy Hammered Knives. I can't wait to get working on this one.