Calico

Thinks s/he gets paid by the post

- Joined

- Apr 16, 2012

- Messages

- 2,941

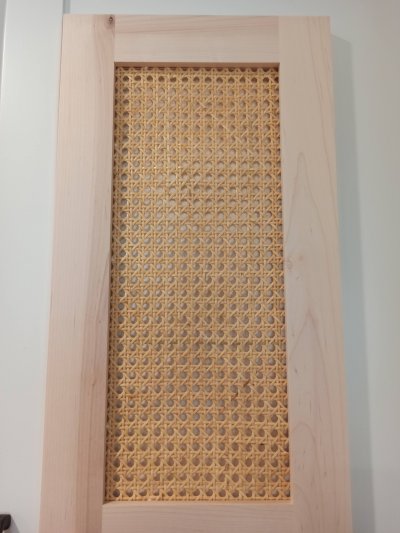

DW wanted a Zoom coffee table and a very specific size. Had a bit of thick walnut and finished it with a few pcs of 4/4 walnut for the top. Did a nice lap joint since I had the 6/4 sides.

Finished with ArmRSeal rubbed on.

That is stunning!

(and catch up on honey-dos...)

(and catch up on honey-dos...)